Taw qhia

Kev lag luam automotive tau ntev dhau los ua tus thawj coj hauv kev siv cov thev naus laus zis los txhim kho kev ua tau zoo, precision, thiab scalability. Ntawm nws cov khoom tseem ceeb tshaj plaws yog lub tsheb thav duab - lub pob txha pob txha uas ua kom muaj kev nyab xeeb, ua haujlwm ntev, thiab kev ua haujlwm. Raws li kev xav tau rau cov khoom siv hnyav, kev hloov kho, thiab kev tsim khoom sai sai, cov tuam ntxhab tau hloov mus rau kev lag luam neeg hlau los hloov pauv cov qauv tsim. Tsab ntawv xov xwm no tshawb txog yuav ua li cas cov neeg hlau tau hloov kho kev tsim cov tsheb thav duab, los ntawm kev tuav cov khoom siv mus rau vuam thiab kev tswj kom zoo, thaum hais txog cov kev cov nyom thiab cov qauv yav tom ntej hauv kev lag luam dynamic.

Tshooj 1: Lub luag haujlwm tseem ceeb ntawm lub tsheb ncej hauv Automotive Design

Tsheb thav duab, feem ntau hu ua chassis, ua lub hauv paus rau tag nrho cov tshuab tsheb. Lawv yuav tsum tiv taus kev ntxhov siab loj, nqus cov kev sib tsoo, thiab txhawb nqa qhov hnyav ntawm lub tsheb thiab nws cov neeg nyob. Cov thav duab niaj hnub no yog tsim los siv cov ntaub ntawv zoo xws li cov hlau muaj zog, aluminium alloys, thiab txawm tias carbon fiber sib xyaw kom sib npaug zog nrog qhov hnyav.

Txawm li cas los xij, kev tsim cov txheej txheem nyuaj no yuav tsum muaj qhov tseeb. Txawm tias me me sib txawv hauv kev sib dhos vuam lossis cov khoom sib dhos tuaj yeem cuam tshuam kev nyab xeeb thiab kev ua haujlwm. Cov txheej txheem phau ntawv ib txwm muaj kev tawm tsam kom ua tau raws li kev ua siab ntev xav tau los ntawm cov qauv tsheb niaj hnub no, tsim kom muaj kev xav tau rau automation.

Tshooj 2: Cov neeg hlau muaj nyob rau hauv Ncej Fabrication: Cov ntawv thov tseem ceeb

2.1 Kev tuav cov khoom thiab kev npaj cov khoom

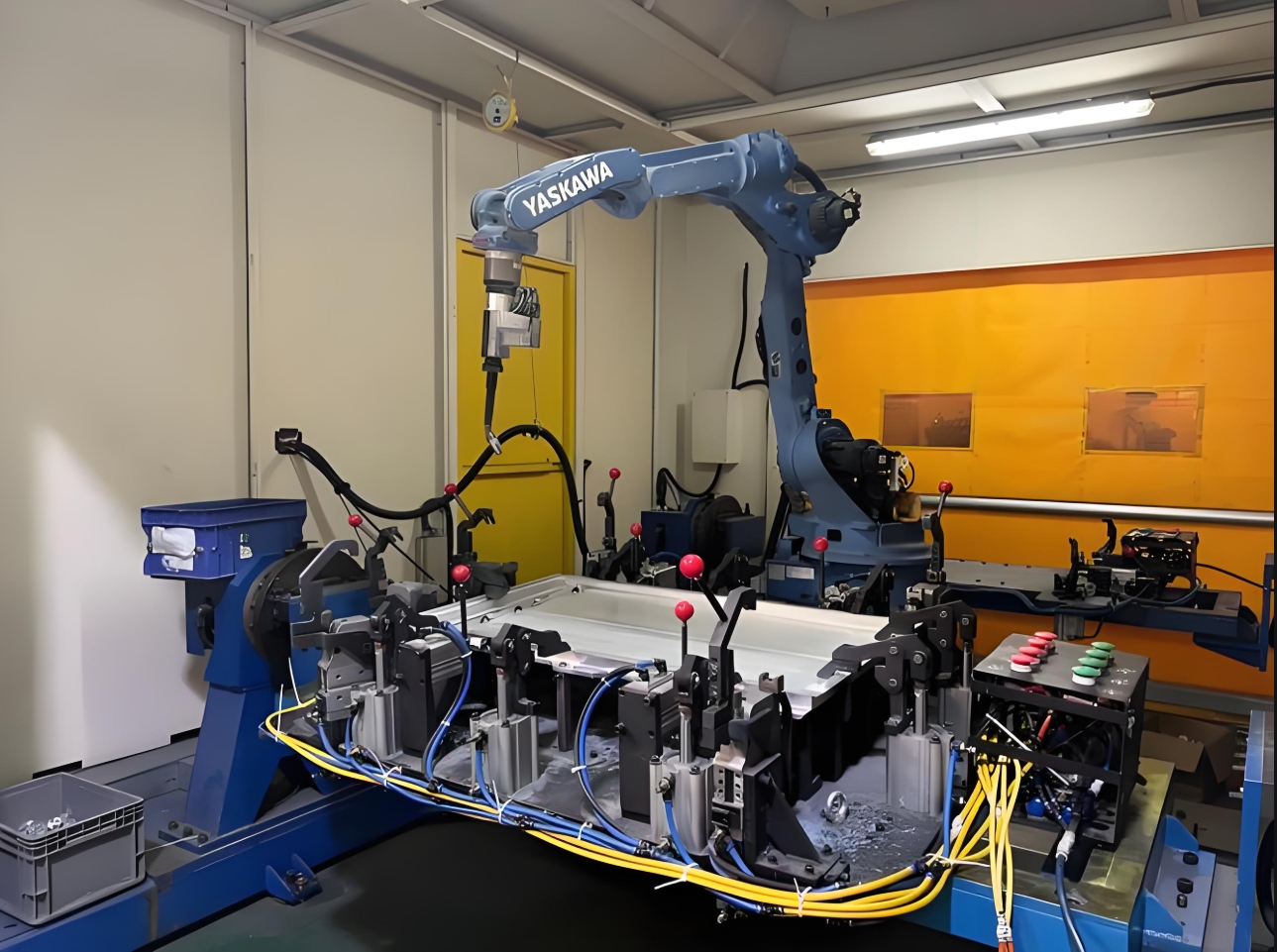

Kev tsim cov automotive thav duab pib nrog cov khoom siv raw. Cov neeg hlau muaj nruab nrog qib siab grippers thiab lub zeem muag zoo tshaj ntawm kev tuav cov ntawv hlau loj, cov raj, thiab cov khoom siv ua ntej. Piv txwv li:

- Sheet hlau manipulation: Robots pre-txiav thiab zoo li steel los yog txhuas ntawv rau hauv thav duab rails, crossmembers, thiab brackets nrog sub-millimeter raug.

- Composite khoom tuav: Cov neeg hlau sib koom tes (cobots) muaj kev nyab xeeb tswj cov khoom hnyav tab sis tsis yooj yim xws li carbon fiber, txo cov khib nyiab thiab tib neeg yuam kev.

2.2 Welding thiab Joining Technologies

Vuam tseem yog cov neeg hlau siv ntau tshaj plaws hauv kev tsim cov ncej. Niaj hnub nimno robotic welding systems xa unparalleled sib xws nyob rau hauv ntau txhiab ntawm weld ntsiab lus:

- Resistance qhov chaw vuam: Multi-axis robots ua qhov chaw vuam ceev ntawm cov hlau thav duab, ua kom muaj zog sib koom ua ke.

- Laser vuam: Precision robots nruab nrog laser hau tsim seamless koom rau txhuas thav ntawv, txo thermal distortion.

- Adhesive daim ntawv thov: Robots siv cov txheej txheem nplaum rau hauv cov qauv nyuaj rau kev sib koom ua ke ntawm cov hlau sib xyaw ua ke, cov txheej txheem yuav luag tsis tuaj yeem rov ua dua manually.

Case Study: Ib tug thawj coj nyob sab Europe automaker txo vuam qhov tsis xws luag los ntawm 72% tom qab xa ib lub nkoj ntawm 6-axis neeg hlau nrog kev hloov kho txoj hauv kev, muaj peev xwm kho qhov vuam tsis raws sijhawm raws li cov lus pom zoo.

2.3 Kev sib dhos thiab kev sib koom ua ke

Lub rooj sib txoos ua ke muaj kev sib koom ua ke ntawm kev ncua kev kawm, lub cav cav, thiab cov khoom siv kev nyab xeeb. Dual-arm robots mimic tib neeg dexterity kom fasten bolts, nruab bushings, thiab kho cov subassemblies. Lub zeem muag-kev coj ua kom ntseeg tau tias cov khoom muaj nyob hauv ± 0.1 hli tolerances, tseem ceeb heev rau kev tswj xyuas kev sib tw tsav tsheb.

2.4 Kev Ua Haujlwm Zoo thiab Kev Ntsuas

Kev tshuaj xyuas tom qab tsim khoom yog qhov tseem ceeb rau kev ua raws li cov cai tswj kev nyab xeeb. Robotic systems tam sim no ua haujlwm:

- 3D laser scanning: Robots qhia tag nrho cov duab geometries txhawm rau txheeb xyuas qhov tsis raug lossis qhov tsis raug.

- Kev kuaj ultrasonic: Automated probes tshuaj xyuas qhov kev ncaj ncees ntawm kev sib txuas yam tsis muaj kev puas tsuaj rau qhov chaw.

- AI-powered defect nrhiav pom: Tshuab kev kawm algorithms soj ntsuam cov koob yees duab pub kom paub txog micro-cracks lossis txheej tsis sib xws.

Tshooj 3: Qhov zoo ntawm Robotic Automation hauv Ncej Ntau Lawm

3.1 Precision thiab rov ua dua

Industrial robots tshem tawm tib neeg kev hloov pauv. Ib lub xov tooj ntawm tes vuam robotic tuaj yeem tuav tau 0.02 hli rov ua dua thoob plaws 24/7 ntau lawm, ua kom txhua tus ncej raws li cov qauv tsim tshwj xeeb.

3.2 Txhim Kho Cov Neeg Ua Haujlwm Kev Nyab Xeeb

Los ntawm automating tej yam txaus ntshai xws li nyiaj siv ua haujlwm vuam lossis nqa hnyav, cov tuam txhab tau tshaj tawm txog 60% txo qis hauv chaw ua haujlwm raug mob ntsig txog kev tsim khoom.

3.3 Tus Nqi Ua Haujlwm

Thaum thawj zaug kev nqis peev tseem ceeb, cov neeg hlau txo cov nqi mus sij hawm ntev los ntawm:

- 30-50% ceev lub sij hawm voj voog

- 20% txo cov khoom pov tseg

- 40% txo cov nuj nqis rov ua haujlwm

3.4 Scalability thiab Flexibility

Modular robotic cells tso cai rau cov tuam txhab tsim kho cov kab ntau lawm sai sai rau cov qauv tsim tshiab. Piv txwv li, hluav taws xob tsheb (EV) thav duab nrog roj teeb enclosures tuaj yeem ua ke rau hauv cov tshuab uas twb muaj lawm nrog tsawg kawg nkaus downtime.

Ntu 4: Kev Sib Tw Sib Tw hauv Robotic Frame Manufacturing

4.1 Cov teeb meem khoom siv sib xws

Kev hloov mus rau ntau cov ntaub ntawv thav ntawv (xws li steel-aluminium hybrids) xav tau cov neeg hlau los ua cov txheej txheem sib txawv. Cov kev daws teeb meem suav nrog:

- Hybrid vuam taub hau sib txuas arc thiab laser technologies

- Sib nqus grippers rau tuav cov hlau tsis muaj hlau

4.2 Programming Complexity

Offline robot programming (OLP) software tam sim no tso cai rau cov engineers simulate thiab optimize robotic workflows digitally, slashing commissioning lub sij hawm mus txog 80%.

4.3 Cybersecurity Risks

Raws li thav duab ntau lawm txuas ntxiv los ntawm Industrial IoT, cov tuam txhab tsim khoom yuav tsum siv cov txheej txheem kev sib txuas lus encrypted thiab hloov kho firmware tsis tu ncua los tiv thaiv cov neeg hlau tes hauj lwm.

Tshooj 5: Lub Neej Tom Ntej ntawm Robotic Frame Manufacturing

5.1 AI-Driven Adaptive Manufacturing

Tom ntej no-tiam neeg hlau yuav leverage artificial txawj ntse rau:

- Self-calibrate cov cuab yeej raws li cov khoom thickness

- Kwv yees thiab them nyiaj rau cov cuab yeej hnav

- Optimize zog noj thaum lub sij hawm ncov xav tau

5.2 Kev Sib Koom Tes ntawm Tib Neeg-Robot

Cobots nrog quab yuam-txwv cov pob qij txha yuav ua haujlwm nrog cov kws tshaj lij rau kev hloov kho zaum kawg, sib txuas tib neeg kev txiav txim siab nrog cov neeg hlau qhov tseeb.

5.3 Sustainable Production

Robotic systems yuav ua lub luag haujlwm tseem ceeb hauv kev ua tiav kev tsim khoom:

- Automated disassembly ntawm qhov kawg-ntawm-lub neej thav duab rau kev rov ua dua tshiab

- Precision khoom deposition kom txo tau cov khoom siv raw

Xaus

Kev sib koom ua ke ntawm kev lag luam robots rau hauv kev tsim cov khoom siv tsheb sawv cev ntau dua li kev txhim kho thev naus laus zis - nws qhia txog kev hloov pauv tseem ceeb hauv kev tsim tsheb li cas thiab tsim. Los ntawm kev xa cov khoom tsis sib xws, kev ua tau zoo, thiab kev yoog raws, cov tshuab neeg hlau txhawb cov tuam txhab kom ua tau raws li cov kev xav tau hloov mus rau kev nyab xeeb, sib dua, thiab muaj kev nyab xeeb dua. Raws li AI, cov sensors siab heev, thiab cov thev naus laus zis ntsuab txuas ntxiv mus rau kev paub tab, kev sib koom ua ke ntawm cov neeg hlau thiab tsheb tsim hluav taws xob yuav ua rau kev lag luam mus rau qib uas tsis tau muaj dua los ntawm kev tsim kho tshiab.

Rau cov tuam txhab tshwj xeeb hauv kev lag luam neeg hlau, qhov kev hloov pauv no nthuav tawm ntau lub sijhawm los koom tes nrog cov neeg tsim khoom hauv kev rov txhais lub neej yav tom ntej ntawm kev txav mus los-ib qho zoo kawg nkaus crafted ib lub sij hawm.

Lus suav1.480 Nws

Cov ntsiab lus tseem ceeb: Automotive thav duab neeg hlau, neeg hlau vuam tshuab, AI hauv kev tsim khoom, kev sib koom tes neeg hlau, kev tsim khoom ruaj khov

Cov lus pom zoo SEO: suav nrog cov lus piav qhia meta tsom rau "automotive ncej automation" thiab "kev lag luam neeg hlau rau lub tsheb chassis." Siv cov kev sib txuas sab hauv rau cov ntaub ntawv tshawb fawb lossis cov nplooj ntawv khoom.

Post lub sij hawm: Mar-26-2025