Ua ntej, tshuab txoj kev tiv thaiv roj

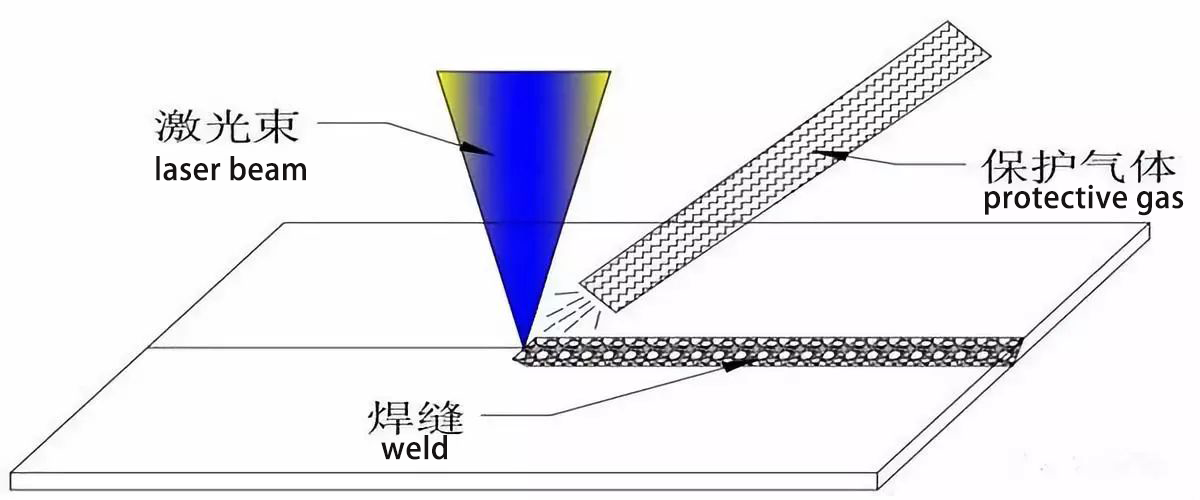

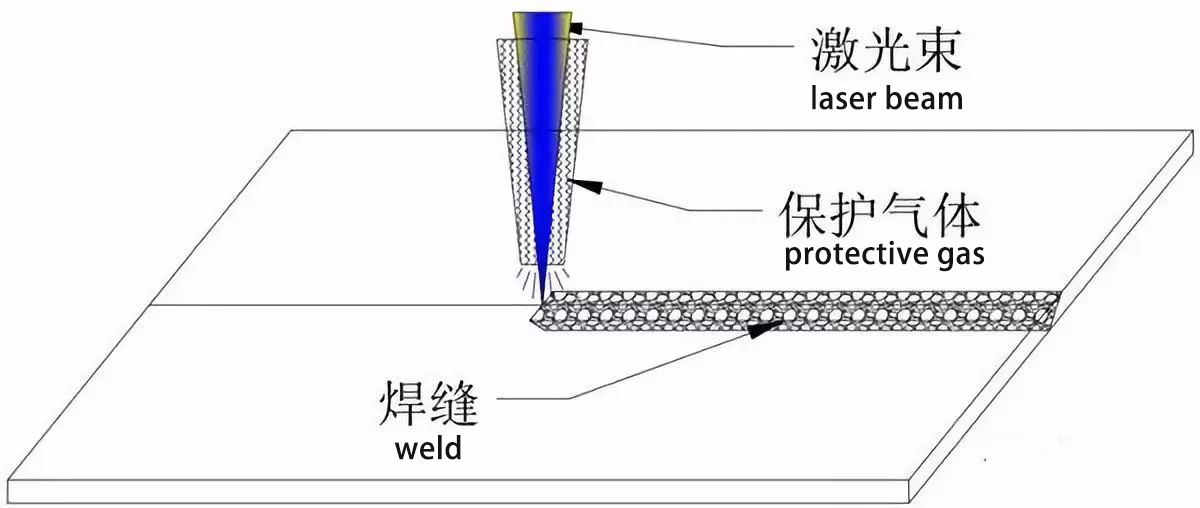

Tam sim no, muaj ob lub ntsiab tshuab ntawm kev tiv thaiv roj: ib qho yog paraxial side-blowing tiv thaiv roj, raws li qhia hauv daim duab 1; Lwm qhov yog coaxial tiv thaiv roj.Qhov kev xaiv tshwj xeeb ntawm ob txoj kev tshuab yog txiav txim siab hauv ntau yam. Feem ntau, nws raug pom zoo kom siv sab tshuab los tiv thaiv cov roj

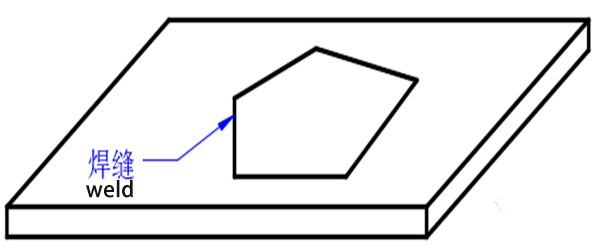

paraxial tshuab tiv thaiv roj

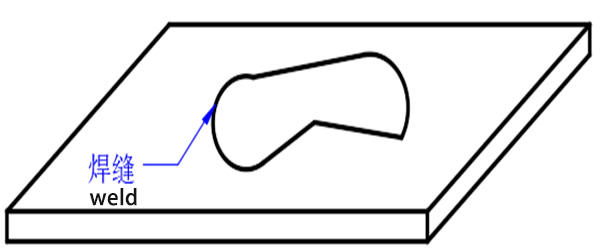

coaxial tshuab tiv thaiv roj

coaxial tshuab tiv thaiv rojOb, kev tiv thaiv roj tshuab hom xaiv txoj cai

Ua ntej, nws yuav tsum tau ua kom paub meej tias qhov hu ua weld yog "oxidized" tsuas yog ib lub npe xwb. Raws li txoj cai, nws yog hais txog cov tshuaj tiv thaiv ntawm cov weld thiab cov khoom tsis zoo nyob rau hauv cov huab cua, uas ua rau lub deterioration ntawm qhov zoo ntawm weld. Nws yog qhov tshwm sim rau cov hlau vuam ua rau cov pa oxygen, nitrogen thiab hydrogen hauv huab cua ntawm qhov kub thiab txias.

Txhawm rau tiv thaiv qhov vuam los ntawm "oxidized" yog kom txo qis lossis zam kev sib cuag ntawm cov khoom siv phom sij nrog cov hlau vuam hauv qhov kub thiab txias. Lub xeev kub kub no tsis yog tsuas yog lub pas dej molten hlau xwb, tab sis tag nrho cov txheej txheem los ntawm lub sij hawm thaum lub vuam hlau yog melted mus rau lub solidification ntawm lub pas dej ua ke hlau thiab nws kub yog txo mus rau ib tug tej yam kub hauv qab no.

Peb, ua piv txwv.

Piv txwv li, titanium alloy vuam, thaum kub siab tshaj 300 ℃ tuaj yeem nqus tau hydrogen sai, ntau dua 450 ℃ tuaj yeem nqus cov pa sai sai, ntau dua 600 ℃ tuaj yeem nqus tau nitrogen sai, yog li titanium alloy vuam seam tom qab solidification thiab kub txo mus rau 300 ℃ hauv qab no theem yuav tsum muaj kev tiv thaiv zoo, txwv tsis pub nws yuav "oxidized".

Los ntawm cov lus piav qhia saum toj no tsis yooj yim rau kev nkag siab, kev tiv thaiv lub tshuab tshuab tsis tsuas yog xav tau sijhawm los tiv thaiv lub pas dej molten, tseem yuav tsum tau welded cia li khov thaj tsam ntawm kev tiv thaiv, yog li feem ntau siv cov paraxial qhia hauv daim duab 1 sab tiv thaiv roj, vim tias txoj kev no cuam tshuam rau txoj hauv kev los tiv thaiv ntau yam kev tiv thaiv coaxial tiv thaiv txoj hauv kev ntawm daim duab 2 yog ntau qhov kev tiv thaiv zoo dua rau thaj tsam ntawm peb.

Paraxial sab tshuab rau kev siv engineering, tsis yog txhua yam khoom siv tuaj yeem siv txoj hauv kev ntawm sab ncej sab tshuab tiv thaiv roj, rau qee yam khoom tshwj xeeb, tsuas yog siv cov roj coaxial tiv thaiv, tshwj xeeb xav tau los ntawm cov khoom tsim thiab kev sib koom ua ke rau kev xaiv.

Plaub, tshwj xeeb tiv thaiv roj tshuab hom xaiv

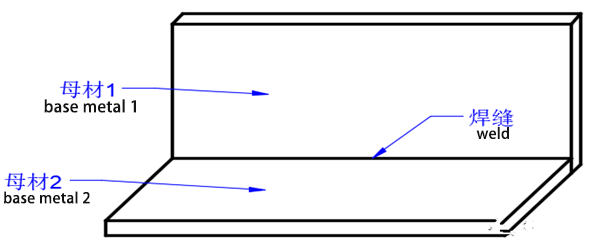

1. Ncaj welds

Raws li pom nyob rau hauv daim duab 3, lub weld zoo ntawm cov khoom yog txoj kab ncaj nraim, thiab daim ntawv sib koom ua ke tuaj yeem yog pob tw, pob qij txha, lub kaum sab xis tsis zoo lossis sib tshooj vuam sib txuas. Rau hom khoom no, nws yog qhov zoo dua los txais yuav lub sideshaft sab tshuab tiv thaiv roj raws li qhia hauv daim duab 1.

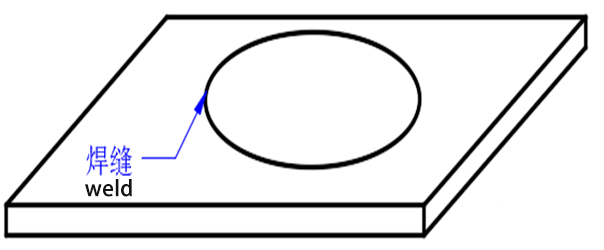

2. Flat kaw graphic weld

Raws li pom nyob rau hauv daim duab 4, lub weld zoo ntawm cov khoom yog dav hlau circumferential zoo, dav hlau multilateral zoo, dav hlau ntau kab kab thiab lwm yam kaw duab. Daim ntawv sib koom ua ke tuaj yeem yog pob tw, pob qij txha, sib tshooj vuam thiab lwm yam. Rau hom khoom no, nws yog qhov zoo dua los siv cov coaxial tiv thaiv roj hom pom hauv daim duab 2.

Kev xaiv cov roj tiv thaiv ncaj qha cuam tshuam rau vuam zoo, kev ua tau zoo thiab tus nqi ntawm cov khoom siv, tab sis vim muaj kev sib txawv ntawm cov khoom siv vuam, nyob rau hauv cov txheej txheem vuam tiag tiag, kev xaiv cov roj vuam yog qhov nyuaj dua, xav tau kev xav txog cov khoom siv vuam, vuam txoj kev, vuam txoj hauj lwm, nrog rau cov kev xav tau ntawm cov khoom siv vuam, los ntawm kev siv vuam zoo dua rau kev xaiv vuam zoo dua.

Source: Vuam Technology

Post lub sij hawm: Sep-02-2021