Taw qhia

Automotive manufacturing sector yog nce kev vam khom rau kev lag luam robots kom ua tiav precision, efficiency, thiab sib xws hauv ntau lawm. Ntawm cov kev siv tseem ceeb tshaj plaws yog kev vuam ntawm cov khoom siv tsheb, tshwj xeebaxles(tseem hu uatsheb axleslos yogtsheb axles), uas yog qhov tseem ceeb rau lub tsheb ruaj khov, kev xa hluav taws xob, thiab kev thauj khoom. Kab lus no tshawb nrhiav seb yuav ua li casrobotic vuam tshuabyog revolutionizing zus tau tej cov axles thiab lwm yam automotive qhov chaw, thaum highlighting lub sab saum toj lo lus tseem ceeb nyob rau hauv ob qho tib siautomotive Cheebtsamthiabvuam robotics.

Tshooj 1: Cov Ntsiab Lus Tseem Ceeb ntawm Automotive hauv Kev Pom Zoo

Automotive manufacturing muaj xws li intricate assemblies, nrog rau cov nram qab no Cheebtsam tseem ceeb heev rau lub tsheb functionality. Ntawm no yog covsab saum toj 5 automotive tivthaiv keywordsmuaj feem xyuam rau qhov kev sib tham no:

- Axle (Lub tsheb qag / tsheb qag)

Axles yog lub hauv paus rau lub tsheb tsav tsheb, txuas lub log thiab txhawb nqa lub tsheb qhov hnyav. Precision welding ua kom muaj kev ncaj ncees thiab ua haujlwm ntev. - Suspension Systems

Cheebtsam xws li tswj caj npab thiab struts yuav tsum muaj welding zoo tiv thaiv txoj kev nyuaj siab. - Tsav tsheb Cheebtsam

Qhov chaw xws li cov vaj tse sib txawv thiab cov kis tau tus mob vam khom rau lub zog muaj zog welds. - Chassis Ncej

Lub nraub qaum ntawm lub tsheb, chassis thav duab xav tau zoo sib xws weld zoo rau kev nyab xeeb. - Exhaust Systems

Complex welds ntawm manifolds thiab kav dej yuav tsum tiv thaiv tshav kub thiab corrosion.

Ntawm no,qag vuamsawv tawm vim nws txoj kev nyuaj thiab cuam tshuam rau kev ua haujlwm ntawm lub tsheb.

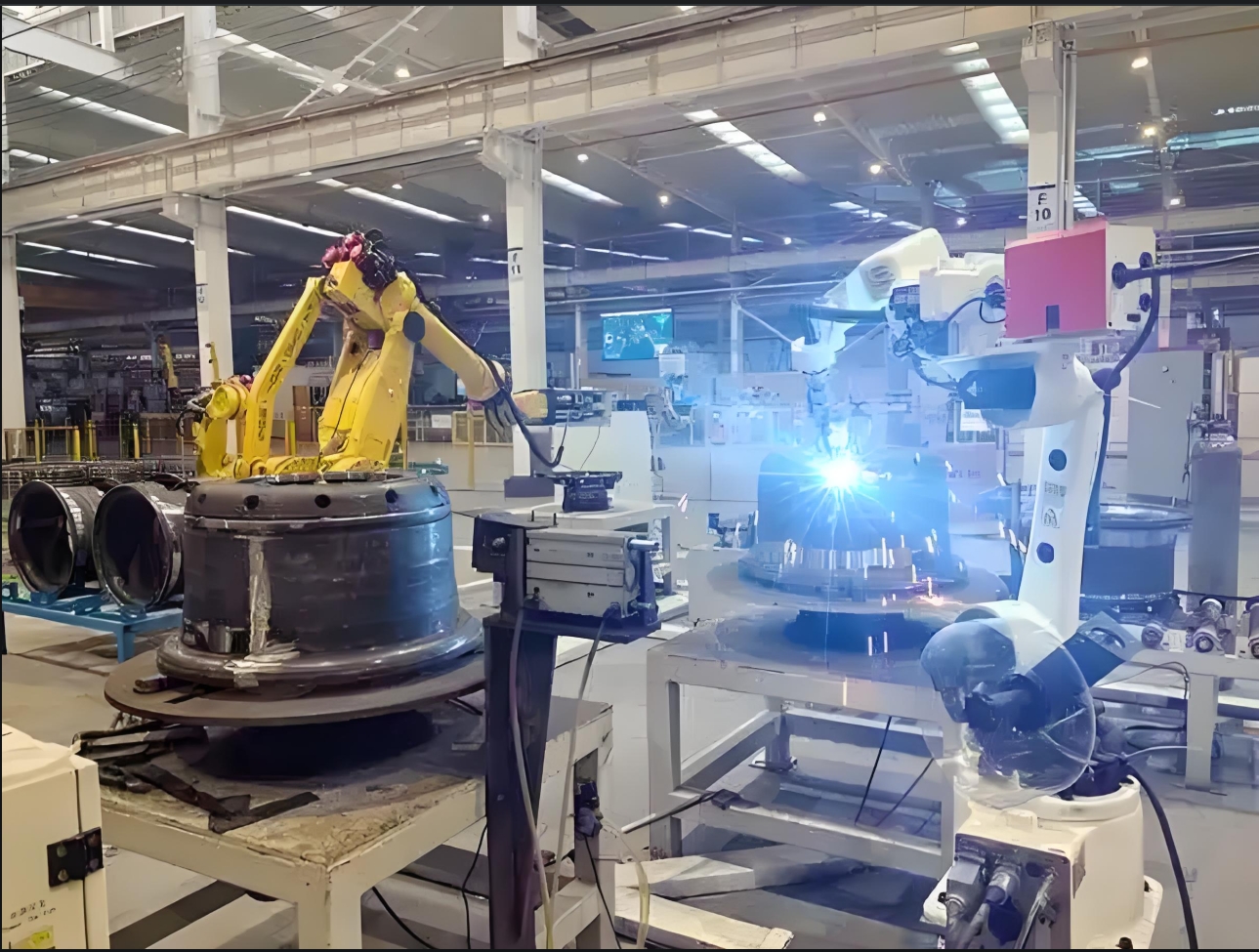

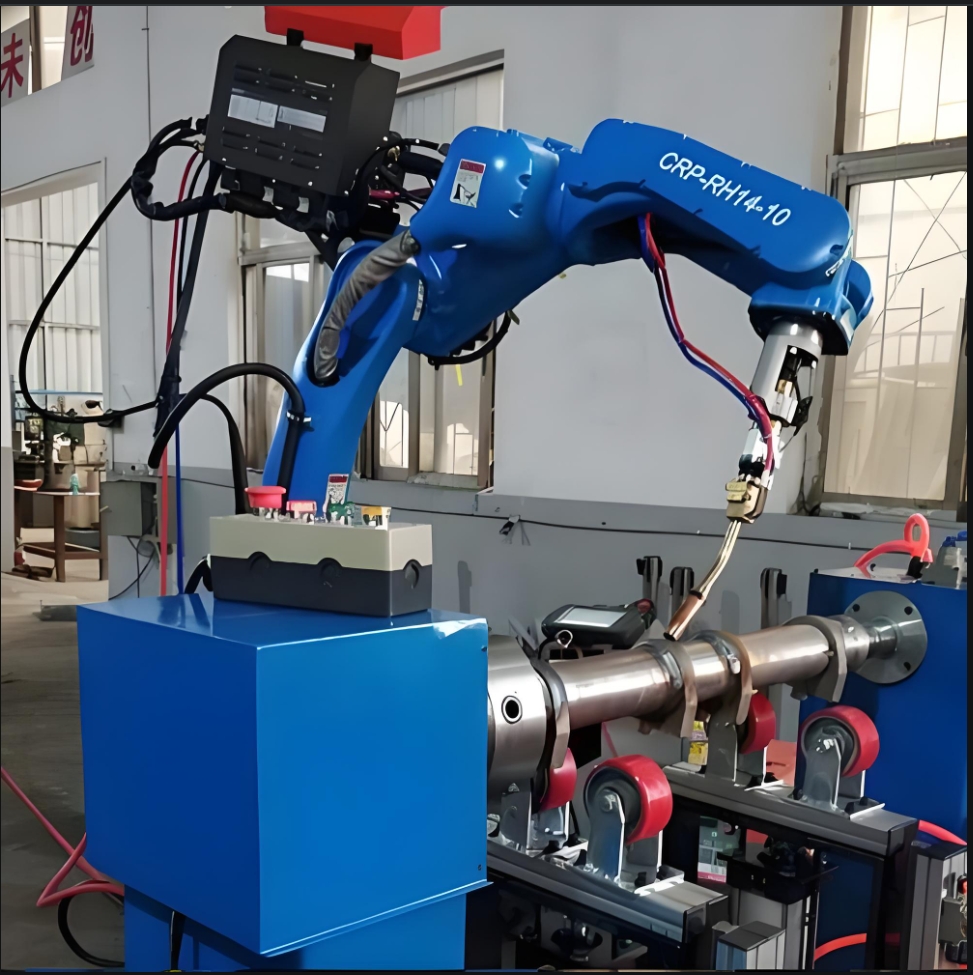

Ntu 2: Kev Lag Luam Vuam Tshuab: Tshuab thiab Muaj Peev Xwm

Niaj hnubrobotic vuam tshuabintegrate advanced technologies kom tau raws li automotive qauv. Hauv qab no yog covsaum 5 vuam neeg hlau lo lus tseem ceeb:

- Automated Vuam

Automation xyuas kom rov ua dua thiab txo tib neeg kev ua yuam kev hauv cov khoom ntim siab. - Arc Welding (MIG / TIG)

Txaus siab rau kev tsim lub qag vim qhov tob tob thiab muaj zog sib koom ua ke. - Laser Vuam

Siv rau kev ua haujlwm siab, xws li welding nyias axle shafts nrog tsawg distortion. - Spot Vuam

Qhov zoo tshaj plaws rau kev koom nrog cov ntawv sib tshooj hlau hauv kev ncua lossis chassis Cheebtsam. - Kev sib koom tes Robots (Cobots)

Txhim khu kev hloov pauv hauv qhov chaw sib xyaw ua haujlwm, ua haujlwm nrog cov kws tshaj lij.

Cov thev naus laus zis no ua rau cov tuam txhab ua tiavxoom-defect weldingntawm cov khoom tseem ceeb xws li axles.

Ntu 3: Vuam Axles nrog Industrial Robots: Txheej Txheem thiab Cov txiaj ntsig

Kauj ruam 1: Tsim thiab Programming

Qag welding pib nrog CAD / CAM simulations los txhim kho txoj kev vuam. Robots yog programmed rau ntau lub axis txav, kom nkag tau mus rau txoj kev geometries.

Kauj Ruam 2: Kev Npaj Khoom Siv

Axles feem ntau yog ua los ntawm cov hlau muaj zog lossis aluminium alloys. Robotic systems ua ntej ntxuav qhov chaw thiab clamp qhov chaw kom txo qis misalignment.

Kauj ruam 3: Vuam Execution

- Arc Vuam: Siv rau cov vaj tse tuab tuab, kom ntseeg tau qhov sib sib zog nqus, sib sib zog nqus seams.

- Laser Vuam: Siv rau precision pob qij txha nyob rau hauv lub teeb yuag qag tsim.

- Seam Tracking Sensors: Xa nyiaj rau cov khoom tsis sib xws hauv lub sijhawm.

Cov txiaj ntsig ntawm Robotic Axle Vuam:

- Ua kom muaj zog: Cov welds tsis tu ncua txo cov ntsiab lus tsis muaj zog.

- Faster Cycle Times: Robots ua haujlwm 24/7, txhawb cov zis.

- Kev txuag nqi: Txo cov nqi seem thiab txo nqi zog.

- Kev nyab xeeb: Tshem tawm cov pa taws thiab pa taws rau cov neeg ua haujlwm.

Tshooj 4: Kev Lag Luam Trends Shaping Robotic Vuam

- AI-Powed Quality Control

Tshuab kev kawm algorithms txheeb xyuas qhov kev ncaj ncees ntawm kev sib tsoo, ua kom pom qhov tsis xws luag hauv lub sijhawm. - Lightweighting Xav

Cov neeg hlau hloov mus rau cov khoom siv zoo xws li aluminium-carbon composites rau hluav taws xob tsheb (EV) axles. - Kev koom ua ke IoT

Cov neeg hlau ntse xa cov ntaub ntawv kev ua haujlwm mus rau hauv nruab nrab lub nruab rau kev saib xyuas kev kwv yees. - Sustainability

Cov txheej txheem siv hluav taws xob siv hluav taws xob txo qis carbon hneev taw.

Cov qauv no txoj hauj lwmrobotic vuam tshuabraws li indispensable nyob rau hauv niaj hnub automotive factories.

Nqe Lus 5: Kev Sib Tw thiab Kev daws teeb meem

Txawm hais tias robotic welding muaj qhov zoo heev, cov kev cov nyom tseem muaj:

- Kev nqis peev siab pib: Mitigated los ntawm ROI mus sij hawm ntev los ntawm kev tsim khoom ntau ntxiv.

- Txoj kev ua haujlwm nyuaj: Simplified ntawm cov neeg siv-phooj ywg interfaces thiab offline simulation cuab yeej.

- Cov khoom sib txawv: Chaw nyob nrog adaptive sensors thiab AI-tsav kev hloov kho.

Rau qag vuam, koom tes nrog kev paubindustrial neeg hlau manufacturersxyuas kom haum cov kev daws teeb meem.

Xaus

Kev vuam ntawm cov khoom siv tsheb xws li axles piv txwv lub zog hloov pauv ntawmindustrial robots. Los ntawm leveragingautomated vuam,arc vuam, thiablaser vuamtechnologies, manufacturers ua tiav unparalleled precision thiab efficiency. Raws li kev lag luam tsheb hloov pauv-tshwj xeeb nrog kev nce ntawm EVs-robotic vuam tshuabyuav nyob twj ywm hauv nruab nrab ntawm kev tsim cov khoom ruaj khov, ua haujlwm siab. Rau cov lag luam nrhiav kev hloov kho lawv cov kab ntau lawm, kev nqis peev hauv kev siv tshuab vuam tshuab tsis yog ib qho kev xaiv xwb tab sis yog qhov tsim nyog.

Ntsiab lus: qag, tsheb qag, Suspension Systems, Drivetrain Cheebtsam, Chassis Ncej; Automated Vuam, Robotic Vuam Systems, Arc Vuam, Laser Vuam, Spot Vuam.

Post lub sij hawm: Apr-02-2025