Kev lag luam automotive yog synonymous nrog innovation, xav tau relentless precision, ceev, thiab kev cia siab rau hauv cov khoom tsim. Ntawm cov khoom tseem ceeb hauv tsheb, cov tshuab tso pa-tshwj xeeb yog cov kav dej tso tawm-ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm ntawm lub tsheb, kev tswj cov pa tawm, thiab txo suab nrov. Raws li cov chaw tsim khoom siv zog ua kom tau raws li cov qauv nruj nruj thiab cov hom phiaj tsim khoom, vuam neeg hlau tau tshwm sim los ua cov cuab yeej tseem ceeb hauv kev tsim cov tshuab pa. Qhov tsab xov xwm no tshawb txog yuav ua li cas robotic vuam tshuab, kev koom ua ke nrog cov cuab yeej zoo tshaj plaws nyob rau hauv zoo lirotary qaij positionersthiabcustomized fixtures, yog revolutionizing zus tau tej cov automotive tso kav, elevating efficiency, sib xws, thiab cov khoom zoo mus rau unprecedented theem.

1. Lub complexity ntawm Exhaust Pipe Manufacturing

Cov kav dej tso pa tawm tau raug mob hnyav, nrog rau qhov kub thiab txias, corrosive gases, thiab mechanical vibrations. Txhawm rau tiv thaiv cov teeb meem no, lawv feem ntau yog tsim los ntawm stainless hlau lossis aluminized steel thiab xav tau seamless, airtight welds thoob plaws geometries nyuaj. Cov txheej txheem vuam cov txheej txheem feem ntau tawm tsam kom muaj kev sib xws hauv cov ntawv thov, ua rau muaj qhov tsis xws luag xws li porosity, tsis tiav fusion, lossis distortion.

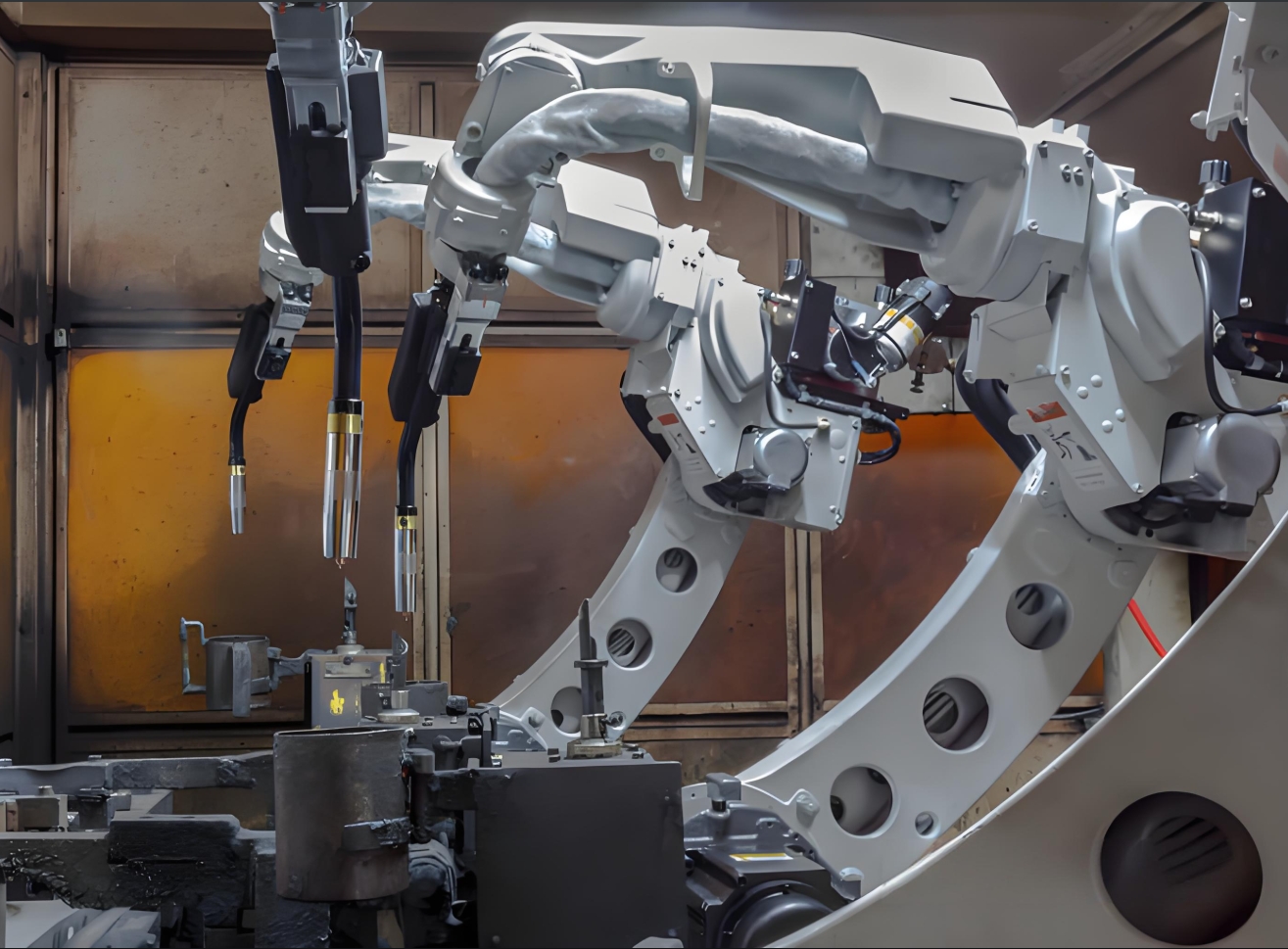

Vuam robots, txawm li cas los xij, ua tau zoo hauv kev daws cov teeb meem no. Nruab nrog ntau-axis articulation thiab synchronized nrog precision positioning systems, lawv xa flawless welds ntawm nkhaus nto, flanges, thiab cov pob qij txha - tseem ceeb heev rau kom ntseeg tau tias cov pa system kev ncaj ncees.

2. Robotic Vuam nyob rau hauv Action: Cov ntawv thov tseem ceeb rau cov kav dej xau

2.1 Tube-rau-Flange thiab Tube-rau-Muffler Vuam

Cov pa hluav taws xob muaj ntau yam khoom, nrog rau cov kav dej, catalytic converters, resonators, thiab mufflers. Robotic welding systems automate qhov kev sib koom ntawm cov raj rau flanges lossis muffler vaj tse, kom ntseeg tau tias muaj kev nkag mus zoo thiab txo qhov cuam tshuam rau qhov chaw sov (HAZ). Piv txwv li, a6-axis articulated neeg hlaumuaj peev xwm maneuver nyob ib ncig ntawm ib tug yeeb nkab ib ncig, tswj kom pom lub teeb lub kaum sab xis thiab mus txawv tebchaws speeds txawm nyob rau hauv contoured nto.

2.2 Laser vuam rau nyias-walled Cheebtsam

Cov kav dej niaj hnub no feem ntau muaj cov txheej txheem nyias-walled los txo qhov hnyav thaum tuav lub zog. Laser vuam robots, nrog lawv lub zog siab ceev thiab nqaim weld seams, tiv thaiv warping thiab khaws cov khoom siv. Qhov no yog tshwj xeeb tshaj yog zoo rau stainless hlau tso tshuab, qhov precision yog qhov tseem ceeb.

2.3 Multi-Pass Vuam rau Thick Joints

Rau cov khoom siv hluav taws xob hnyav hauv cov tsheb ua lag luam, cov tshuab hluav taws xob hlau hlau arc vuam (GMAW) ua haujlwm ntau dhau welds los tsim cov pob qij txha ruaj khov ntawm cov kav dej tuab thiab cov hlua khi. Adaptive welding algorithms kho qhov tsis sib xws hauv lub sijhawm tiag tiag kom haum rau cov khoom sib txawv.

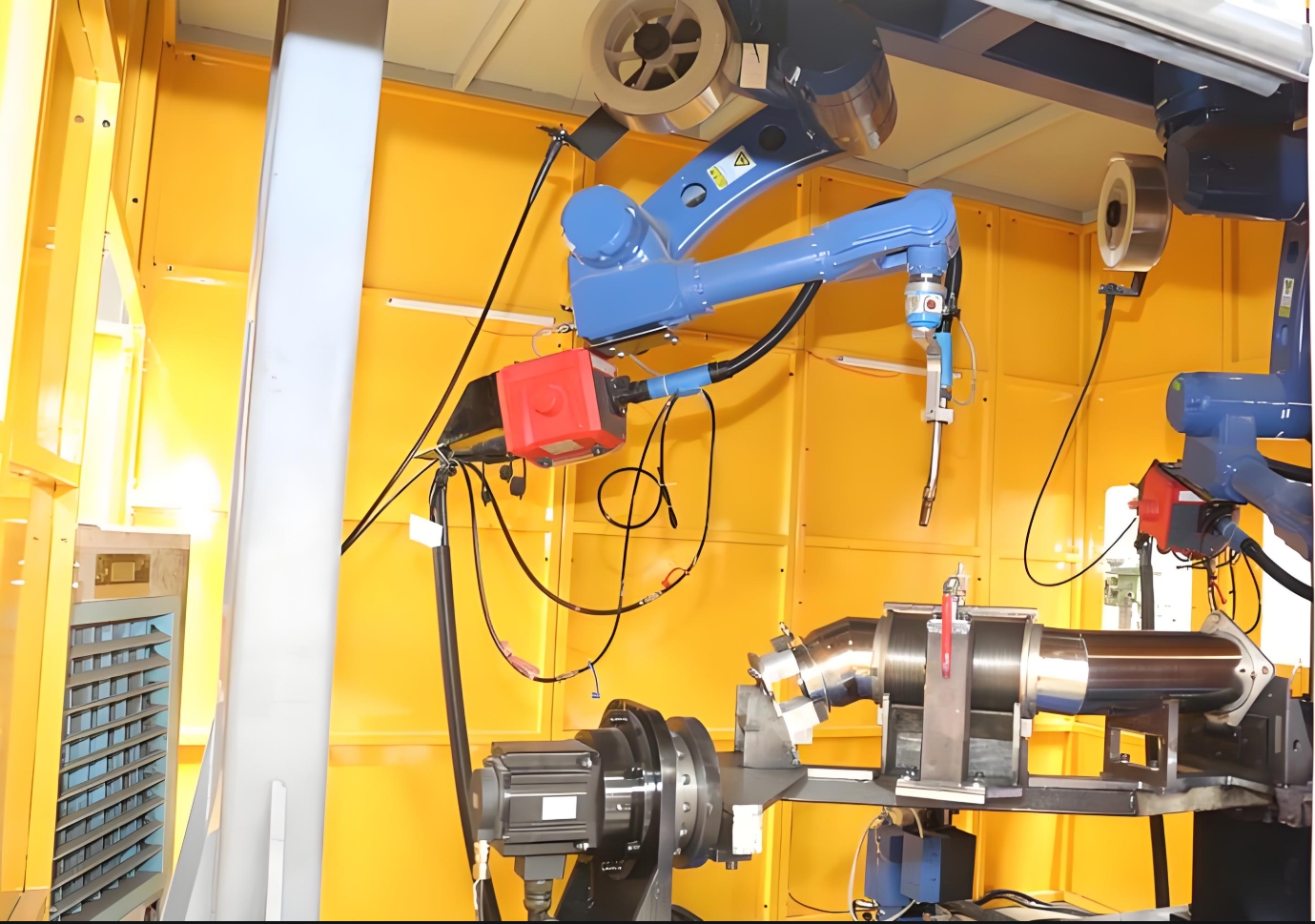

3. Txhim khu kev yooj yim nrog Rotary Tilt Positioners

Ib tug neeg hlau welding cell lub efficiency hinges ntawm seamless kev sib koom tes ntawm tus neeg hlau thiab workpiece.Rotary qaij positionersyog qhov tseem ceeb hauv cov txheej txheem no, ua kom 360-degree kev sib hloov thiab tilting ntawm cov kav dej thaum lub sij hawm vuam. Cov txiaj ntsig muaj xws li:

- Optimal Joint Accessibility: Tus positioner reorients cov yeeb nkab los nthuav qhia cov vuam seam nyob rau hauv lub tiaj tus los yog kab rov tav txoj hauj lwm, simplifying neeg hlau programming thiab txo lub sij hawm voj voog.

- Txo Repositioning: Los ntawm dynamically kho lub workpiece, tus neeg hlau tuaj yeem ua tiav ntau yam welds hauv ib qho kev teeb tsa, txo lub sijhawm tsis ua haujlwm.

- Txhim kho Ergonomics: Cov neeg ua haujlwm thauj khoom / tshem tawm cov khoom thaum cov neeg hlau welds, maximizing throughput.

Piv txwv li, ib tug dual-chaw nres tsheb positioner tso cai rau ib tug yeeb nkab yuav welded thaum lub tom ntej no loaded, ua tiav nyob ze-nruam ntau lawm.

4. Precision Fixturing: Cov pob txha ntawm kev sib raug zoo

Customizedvuam fixturesNws yog ib qho tseem ceeb rau kev tuav cov khoom seem hauv kev sib raug zoo thaum lub sij hawm vuam robotic. Cov ntsiab lus tseem ceeb ntawm kev tsim qauv muaj xws li:

- Clamping Mechanisms: Pneumatic lossis hydraulic clamps ruaj ntseg cov kav dej, flanges, thiab brackets yam tsis muaj qhov sib tsoo.

- Modularity: Cov kev hloov pauv ceev kom haum rau cov yeeb nkab sib txawv lossis cov teeb tsa, zoo tagnrho rau cov qauv sib xyaw.

- Thermal Management: Fixtures ua los ntawm cov ntaub ntawv kub-resistant tiv taus ntev raug rau vuam arcs.

Advanced fixtures integrates sensors los xyuas qhov kev tso kawm ntawm cov khoom ua ntej vuam commences, tshem tawm misalignment tsis xws luag.

5. Quantifying Efficiency Gains

Kev saws me nyuam ntawm robotic vuam tshuab nyob rau hauv cov pa yeeb nkab raug muab kev txhim kho ntsuas:

- Lub sij hawm txo: Ib tug neeg hlau MIG welder tuaj yeem ua tiav ib lub voj voog ncig hauv 60 vib nas this, piv rau 180+ vib nas this rau phau ntawv vuam.

- Siab Uptime: Robots ua haujlwm 24/7 nrog tsawg kawg nkaus downtime, boosting txhua xyoo tso zis los ntawm 30-50%.

- Kev txuag khoom: Precise parameter control txo spatter thiab rework, txo tus nqi consumable los ntawm 15-20%.

Piv txwv li, tus neeg muag khoom tsheb Tier-1 tau tshaj tawm a40% nce nyob rau hauv throughputTom qab xa cov hlwb neeg hlau nrog synchronized positioners rau kev sib sau ua ke.

6. Ua kom zoo rau Automotive Standards

Robotic welding xyuas kom ua raws li cov qauv zoo ntawm tsheb xws li IATF 16949:

- Rov ua dua: Robots replicate weld paths nrog ± 0.1 hli raug, tshem tawm tib neeg kev hloov pauv.

- Defect Detection: Integrated vision systems or arc monitoring sensors detect irregularities mid-process, triggering immediate corrections.

- Cov ntaub ntawv: Automated systems tsim traceable weld cav, tseem ceeb rau kev soj ntsuam thiab rov qab.

Kev soj ntsuam tom qab vuam qhia tau hais tias cov tshuab neeg hlau txo cov porosity thiab tawg tus nqi ntau dua 90% piv rau cov txheej txheem phau ntawv.

7. Sustainability thiab yav tom ntej Trends

Automotive manufacturers tau nce qhov tseem ceeb ntawm kev ruaj ntseg. Robotic welding txhawb qhov kev hloov no los ntawm:

- Txo kev siv hluav taws xob: Lub sij hawm arc-on tau zoo thiab kev ua kom zoo tshaj plaws ua rau txo qis kev siv hluav taws xob.

- Txo cov khib nyiab: Siab dua first-pass yield tus nqi txo cov seem.

- Ua kom lub teeb yuag: Precision welding pab txhawb kev siv cov khoom siv siab heev, thinner yam tsis muaj kev cuam tshuam ntev.

Saib tom ntej,AI-tsav vuam robotsyuav leverage tshuab kev kawm rau tus kheej-optimize tsis rau cov ntaub ntawv tshiab, thaumkev sib koom tes robots (cobots)yuav pab cov neeg ua haujlwm hauv kev tsim khoom me me.

Xaus

Nyob rau hauv high-stakes realm ntawm automotive tso system manufacturing, vuam robots-augmented los ntawm ntse positioners thiab fixtures-sawv cev lub pinnacle ntawm precision engineering. Los ntawm automating txoj haujlwm vuam txoj haujlwm, cov tshuab no txhawb cov tuam txhab kom ua tiav lub voj voog nrawm dua, tsis muaj qhov tsis zoo, thiab kev tsim ntau lawm. Raws li cov kev cai emissions nruj thiab lub tsheb tsim tau hloov zuj zus mus, robotic vuam tshuab yuav nyob twj ywm lub hauv paus ntawm innovation, tsav tsheb kev lag luam mus rau ib tug ntse dua, huv si yav tom ntej.

Rau cov tuam txhab lag luam neeg hlau, hais txog cov peev txheej no hauv kev siv cov yeeb nkab tsis yog tsuas yog qhia txog kev txawj ntse tab sis kuj tseem muab lawv cov kev daws teeb meem los ua cov koom tes tseem ceeb hauv kev ua kom zoo tshaj plaws hauv kev tsim tsheb.

Post lub sij hawm: Mar-21-2025