4 Axis Stamping Neeg Hlau Rau Xovxwm Tshuab

Khoom Taw Qhia

Raws li qhov xav tau tiag tiag rau kev txhim kho thiab kev hloov pauv ntawm kev lag luam stamping, kev ua haujlwm siab thiab kev tswj tau yooj yim 4-Axis stamping tuav neeg hlau yog tsim thiab tsim.

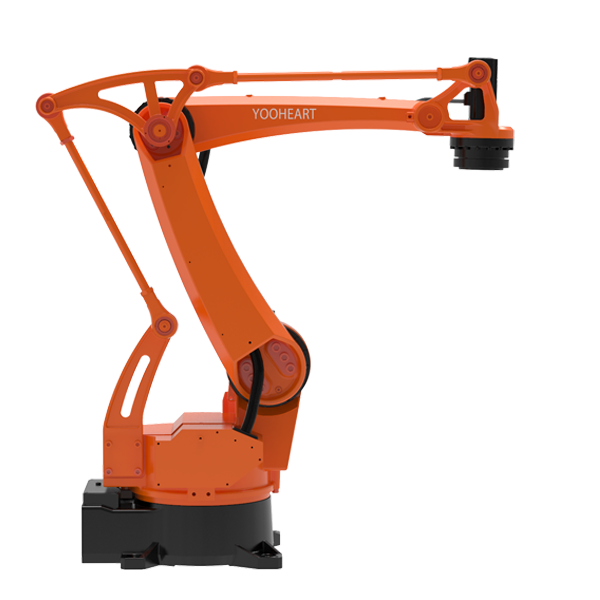

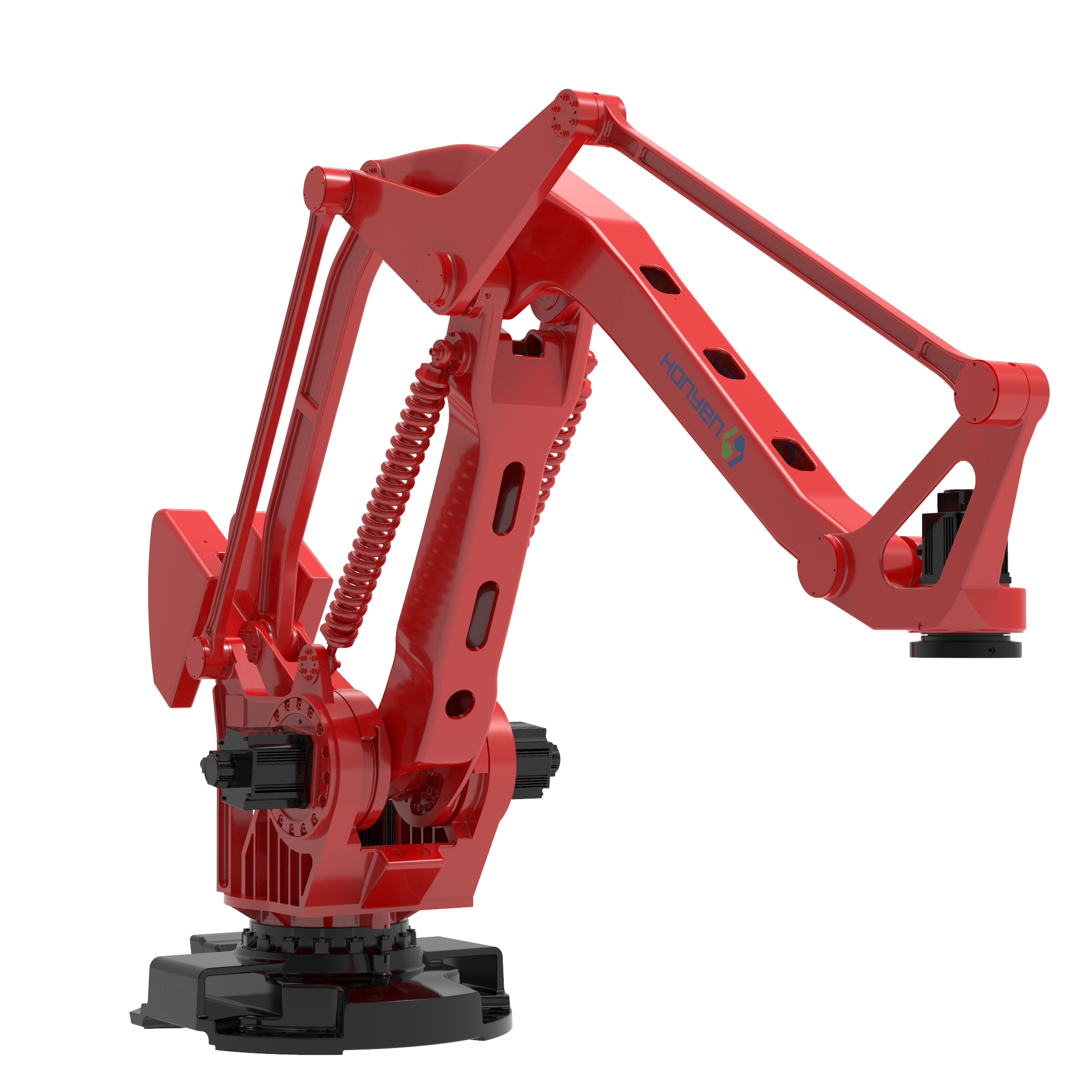

Plaub axis stamping neeg hlau txais plaub axis tsim, compact duab, me me, lub teeb yuag, dav siv hauv argon arc vuam, palletizing, tuav, stamping thiab lwm yam, tuaj yeem ua tiav kev tuav ruaj khov, vuam raug.Plaub axis xuas nrig ntaus manipulator tuaj yeem ua haujlwm stamping yooj yim hauv qhov chaw me me, thiab nws yooj yim thiab yooj yim rau nruab thiab debug.

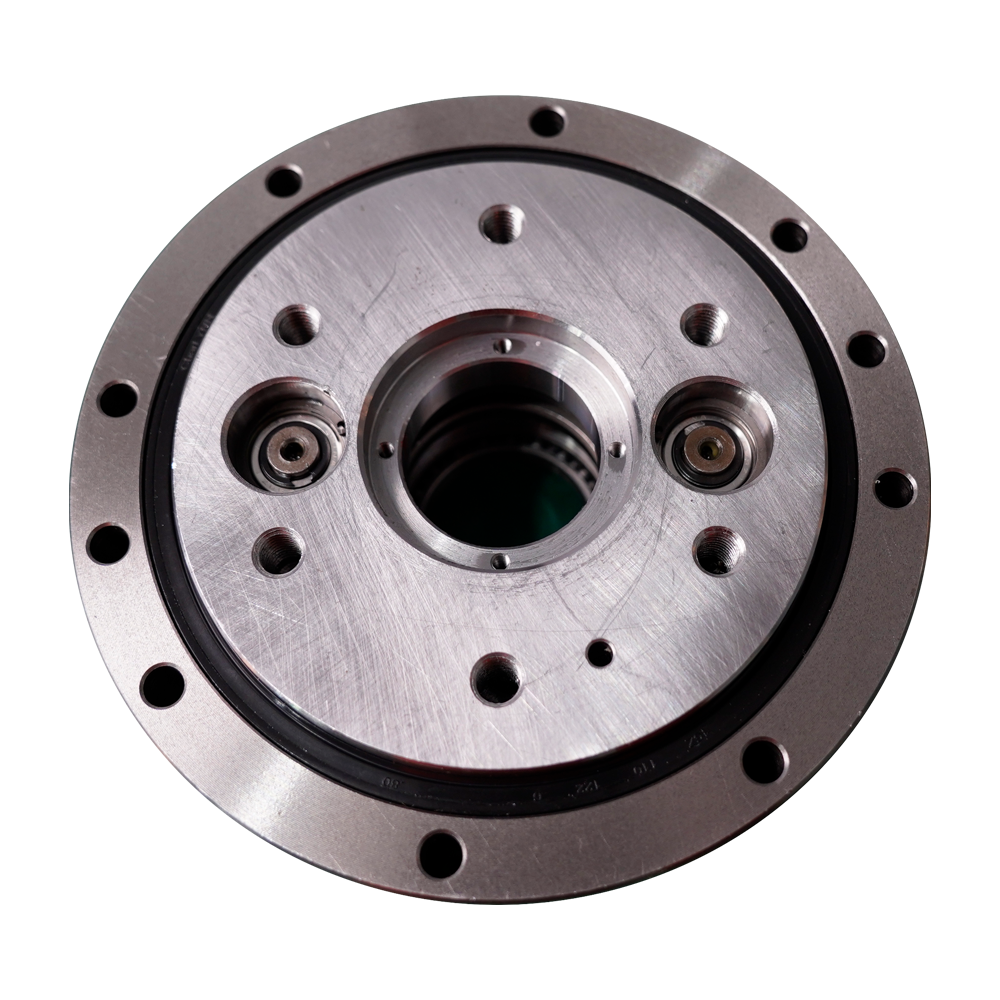

Core Parts

Tag nrho cov khoom lag luam zoo hauv Suav teb

Servo Tsav

Lub hom ntawm servo lub cev muaj zog yog Ruking, Suav hom nrog qhov zoo ntawm cov tshuaj tiv thaiv sai, loj torque rau inertia piv ntawm pib torque thiab lwm yam.Nws tuaj yeem tiv taus kev ua haujlwm hnyav uas ua haujlwm ntau heev rau pem hauv ntej thiab rov qab acceleration thiab deceleration ua haujlwm thiab tuaj yeem tiv taus ntau zaus ntawm kev tshaj tawm hauv lub sijhawm luv luv.

LNC CONTROL SYSTEM

Yooheart neeg hlau txais kev qhia kev qhia.Nws yog qhov yooj yim thiab yooj yim thiab yoog raws hauv kev ua haujlwm.Yooheart neeg hlau kuj tseem txhawb nqa cov kev pab cuam tej thaj chaw deb, uas tuaj yeem siv rau ntau yam ntawm cov haujlwm nyuaj.

ROBOT lub cev

Lub cev tau txais cov txheej txheem tuag casting, siv cov pwm kab noj hniav los thov kev kub siab rau lub melting hlau tsim, lub cev tsim muaj siab ceev, muaj zog rigidity, nws tus kheej hnyav yog sib dua.

Qhia kom meej

Siab Precision

Cov lus teb ceev ceev

Thiab qib yog thawj

nyob rau hauv lub teb chaws

Yooj yim hauv cov qauv

Yooj yim khaws cia

Tus nqi ntau dua

Kev kub ceev thiab ruaj khov

Txoj kev meej

Zoo meej Stamping daws

Neeg hlau Parameter

| Qhov project | Specification | Qhov project | Specification | Axis | Motion range | Max ceev | Hollow Dia |

| Axis | 4 | Kub | 0 ℃ -45 ℃ | J1 | ± 170º | 190º / s | —— |

| Muaj peev xwm | 3.7 kWv | Cov av noo | 20-80% RH (tsis muaj av noo) | J2 | + 10º ~ + 125º | 120º / s | —— |

| Qhov hnyav | 170 KG | Kev vibration | Hauv qab 4.9M / S ² | J3 | + 10º ~ 95º | 120º / s | —— |

| Max payload | 10 KG | Lwm tus | Tsis muaj hluav taws kub thiab corrosive gases thiab kua, kom deb ntawm hluav taws xob cov suab nrov | J4 | ± 360º | 200º / s | —— |

| Max ua haujlwm ntau yam | 140 cm | Rov ua dua | ± 0.08 hli | IP qib | IP65 | Kev teeb tsa | Hauv av |

Kev thov neeg hlau

Kub extrusion khoom loading thiab unloading

Qhov project no tsuas yog rau tooj liab stamping txoj kev.Txoj kev xuas nrig ntaus liab yog txheej txheem kub extrusion.Thaum lub sij hawm liab xuas nrig ntaus, cov khoom hlau yog rhuab mus rau ib qho kub thiab muab tso rau hauv preheated pwm.Tom qab ib lub sij hawm reciprocating txav ntawm lub cuab yeej siv lub siab, cov khoom siv hlau yog cov yas deformed kom tau raws li qhov yuav tsum tau muaj qhov loj me, cov duab thiab cov khoom zoo ntawm cov khoom stamping.Cov neeg siv khoom siv Yooheart 4-axis tuav neeg hlau kom thauj khoom thiab tshem tawm cov hlau xuas nrig ntaus hlau ua haujlwm

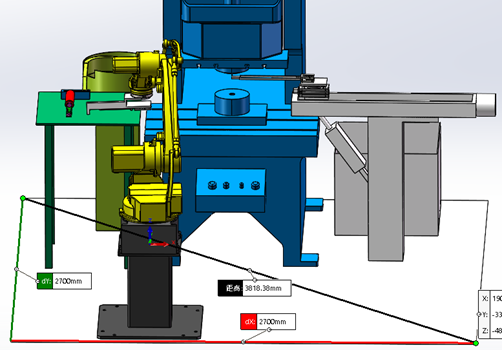

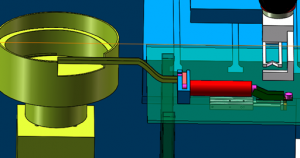

Integration Solution Overview

Peb tes num muaj xws li ib tug xuas nrig ntaus xovxwm, Yunhua 4-axis 10kg neeg hlau, thib ob positioning tooling, lub tog raj kheej ua ke blanking ntaus ntawv thiab hais txog.Cov ntaub ntawv paub xws li lub sijhawm sib tw, ntsuas kev thauj khoom thiab kev ua haujlwm yog txhua yam nyob rau hauv qhov ntsuas qhov ntsuas ntawm HY1010B-140.

Txheej txheem ntau lawm Txheej txheem cej luam

Phau ntawv pub rau hoist ▶ kev vibration phaj pub ▶ Muab tso rau ntawm cov khoom noj ua ntej cua sov ▶ eddy tam sim no raj cua sov ▶ theem nrab qhov chaw fixture positioning ▶ neeg hlau clamping ▶ xuas nrig ntaus ▶ lub tog raj kheej pub khoom tso tawm

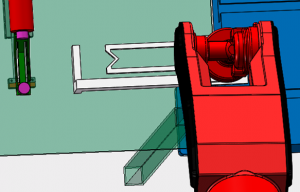

Summary of feeding and positioning device action

Pub vibration phaj manually ▶ Lub vibration phaj yog cov khoom siv rau lub eddy tam sim no cua sov raj ▶ Qhov thib ob qhov chaw yog neeg hlau clamp positioning

Txheej txheem cej luam ntawm clamping ntaus ntawv ua

Tus neeg hlau yuav clamp positioned tooj liab cov ntaub ntawv ▶ rau punch txoj kev

Kev Pabcuam Tomqab Muag

Peb muaj qhov zoo tshaj plaws tom qab kev pabcuam los pab koj kawm txog kev ua haujlwm txawm tias koj tsis tau siv cov neeg hlau ua haujlwm thiab daws teebmeem thaum koj siv sijhawm.

Ua ntej, peb yuav muab cov ntaub ntawv ntsig txog los pab koj nkag siab qee cov ntaub ntawv neeg hlau.

Qhov thib ob, peb yuav muab cov yeeb yaj kiab qhia.Koj tuaj yeem ua raws cov yeeb yaj kiab no ib kauj ruam los ntawm kev xaim, kev ua haujlwm yooj yim kom ua tiav cov haujlwm nyuaj.Nws yog txoj hauv kev zoo tshaj plaws los pab koj nyob rau hauv qhov xwm txheej covid.

Qhov kawg tab sis tsis kawg, peb yuav muab kev pabcuam online nrog ntau tshaj 20 tus kws tshaj lij.Yog tias koj muaj lus nug, koj tuaj yeem tiv tauj peb txhua lub sijhawm thiab peb yuav pab koj sai.

RFQ

Q. Qhov no puas muaj kev nyab xeeb rau cov neeg ua haujlwm?

A. paub meej, ib qho ntawm qhov zoo ntawm kev siv neeg hlau rau kev xaiv thiab qhov chaw yog tiv thaiv cov neeg ua haujlwm los ntawm kev raug mob.Ib tus neeg ua haujlwm tuaj yeem tuav 5 ~ 6 units CNC tshuab.

Q. Yam khoom twg tuaj yeem siv thauj khoom thiab tshem tawm neeg hlau?

A. Txhua lub tshuab hluav taws xob tshuab hluav taws xob tuaj yeem ua tau raws li qhov kawg-ntawm-arm-tooling uas yog sib xws nrog koj lub tshuab thiab cov khoom.Lawv yog cov tsis tshua muaj tseeb thiab kuj muaj lub dexterity los tuav ib feem nrog kev saib xyuas.

Q. Tsuas yog ib qho kawg ntawm caj npab tuaj yeem siv rau kev thauj khoom thiab tshem tawm neeg hlau?

A. Muaj cov neeg hlau caj npab tuaj yeem hloov kho qhov kev zov me nyuam thiab cov hlua khi, kev hloov pauv sai hauv cov khoom siv ntse, kev debugging ceev, tshem tawm qhov xav tau ntawm cov neeg ua haujlwm tab sis kuj rau lub sijhawm kev cob qhia, tuaj yeem muab tso rau hauv ntau lawm.

Q. Puas muaj lwm yam kev tsim nyog ntawm kev thauj khoom thiab tshem tawm neeg hlau?

A. Txhim kho qhov zoo ntawm cov khoom ua haujlwm zoo: cov neeg hlau automated ntau lawm kab, los ntawm kev pub mis, clamping, txiav tag nrho los ntawm cov neeg hlau, kom txo tau cov kev sib txuas nruab nrab, ib feem zoo yog zoo heev, tshwj xeeb tshaj yog zoo nkauj nto.

Q. Koj puas tuaj yeem muab tag nrho cov kev daws teeb meem rau kev thauj khoom thiab tshem tawm neeg hlau?

A. paub meej, peb tuaj yeem ua qhov ntawd ua ke nrog peb tus neeg muag khoom.