Bingo TIG welding tshuab

Saib Peb Ua Haujlwm!

Nto moo Model Follow

TIG welding Fais fab qhov chaw, Phau Ntawv & Cov Qauv Neeg Hlau, Txhawb kev sib txuas lus sib txawv

WSME 315/400/500/630

Inverted AC thiab DC mem tes argon arc vuam tshuab

Muaj nuj nqi:

AC tas li tam sim no TIG, AC pulse TIG, DC tas li tam sim no TIG, AC mem tes TIG, phau ntawv kev puas siab puas ntsws-arc vuam.

Daim ntawv thov kev lag luam:

Aerospace, chaw faib, petrochemical kev lag luam, tshav kub exchanger, aluminium rooj tog thiab tsheb kauj vab teeb.

Nta:

Lub vaj huam sib luag ua haujlwm nrog cov qauv tsim nyog, kev ua haujlwm nplua nuj thiab kev ua haujlwm yooj yim;

◆ Lub vuam parameter tuaj yeem raug presetly;

◆ Lub AC zaus thiab tu dav tuaj yeem hloov kho ntawm nws tus kheej kom ua tau raws li qhov xav tau ntawm cov txheej txheem vuam rau cov khoom txhuas sib txawv;

◆ Nws muaj qhov yooj yim arc tawm tsam, ruaj khov hluav taws xob arc thiab tswj tau yooj yim vuam pas dej;

◆ Argon arc vuam tuaj yeem tiv thaiv rab phom vuam los ntawm dej depletion;

◆ Lub vuam tam sim no tuaj yeem tswj tau deb;

◆ Lub weld nkag mus thiab weld dav yuav tsum tau los ntawm lub weld ob leeg thiab tus naj npawb ntawm waveform tuaj yeem tau los ntawm kev hloov ntawm cov mem tes tam sim no, impulse zaus, lub luag hauj lwm piv, alternating tam sim no, AC zaus, tu proportions thiab AC bias ratio thaum lub AC argon arc welding yog siv los ua kom lub neej ntev kev pab cuam, tshwj xeeb tshaj yog muaj feem xyuam rau cov vuam tsis siv neeg thiab cov neeg hlau vuam.

| Qauv | WM-315R | WM-400 | WM-500 | NWS-630 |

| Rated input voltage / zaus | Peb-theem 380V (+/-) 10% 50Hz | |||

| Rated input muaj peev xwm (KVA) | 12.1 | 17.1 | 25.7 ib | 34.7 ib |

| Rated input tam sim no (A) | 18.5 Nws | 26 | 39 | 53 |

| Rated load sustainability (%) | 60 | 60 | 60 | 60 |

| Cov zis tsis muaj hluav taws xob (V) | 63 | 70 | 79 | 79 |

| Output tam sim no ntau yam (A) | 5-315 : kuv | 5-400 Nws | 20-500 Nws | 20-630 Nws |

| Arc pib tam sim no (A) | 10-315 : kuv | 10-400 Nws | 20-500 Nws | 20-630 Nws |

| Peak tam sim no (A) | 5-315 : kuv | 10-400 Nws | 20-500 Nws | 20-630 Nws |

| Arc nres tam sim no (A) | 5-315 : kuv | 10-400 Nws | 20-500 Nws | 20-630 Nws |

| Pre-flow lub sij hawm (S) | 0.1 ~ 15 | |||

| Lagging lub sij hawm ntawm gas-stopping (S) | 0.1 ~ 20 | |||

| Pulse zaus (Hz) | 0.2 ~ 20 | |||

| Pulse lub luag haujlwm (%) | 1 ~ 100% | |||

| AC zaus (Hz) | 20-200 Nws | 20-200 Nws | 20-100 Nws | 20-100 Nws |

| TIG pilot arc style | HF arc | |||

| Thrust tam sim no (A) | 30-315 : kuv | 50-400 | 50-500 | 50-630 Nws |

| Txias hom | Dej txias | |||

| Rwb thaiv tsev qib | H/B | |||

WM 315/400/500

Inverted DC pulse argon arc vuam tshuab

Muaj nuj nqi:

DC tas li tam sim no TIG, DC pulse TIG, phau ntawv hlau-arc vuam.

Daim ntawv thov kev lag luam:

Petrochemical kev lag luam, siab nkoj, hluav taws xob siv hluav taws xob, nkoj, tsheb kauj vab, nuclear fais fab thiab cov yeeb nkab tso.

Nta:

◆ Lub vaj huam sib luag ua haujlwm nrog cov qauv tsim nyog, kev ua haujlwm nplua nuj thiab kev ua haujlwm yooj yim;

◆ Cov yam ntxwv xws li qhov nce qeeb thiab qhov qis qis ntawm cov hluav taws xob tam sim no, impulse zaus, lub luag hauj lwm piv, lub sij hawm ntawm cov khoom siv roj siab heev thiab cov khoom lag luam roj tuaj yeem raug precisely;

◆ Phau ntawv hlau-arc vuam tuaj yeem kho cov hluav taws xob tam sim no ntawm arc striking thiab thrust, nrog ib qho yooj yim striking ntawm arc thiab tiv thaiv cov adhesion ntawm vuam pas nrig;

◆ Argon arc vuam tuaj yeem tiv thaiv rab phom vuam los ntawm dej depletion;

◆ Nws muaj ob-kauj ruam thiab plaub-kauj ruam vuam tswj hom;

◆ Nws yog me dua thiab sib dua thiab yooj yim rau kev txav mus los;

◆ Tam sim no thiab qhov voltage tuaj yeem tshwm sim ib txhij.Lub vuam tam sim no tuaj yeem raug presetly;

◆TIG tuaj yeem xaiv txoj hauv kev ntawm kev nqa lub zog siab ntawm arc tawm tsam.

| Qauv | WM-315 | WM-400 | WM- 500 | ||

| Rated input voltage / zaus | Peb-theem 380V (+/-) 10% 50Hz | ||||

| Rated input muaj peev xwm (KVA) | 11.2 | 17.1 | 23.7 ib | ||

| Rated input tam sim no (A) | 17 | 26 | 36 | ||

| Rated load sustainability (%) | 60 | 60 | 60 | ||

| DC qhov tam sim no Vuam tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 | ||

| DC mem tes | Peak tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 | |

| Base tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 | ||

| Pulse lub luag haujlwm (%) | 1 ~ 100 | ||||

| Pulse zaus (Hz) | 0.2 ~ 20 | ||||

| TIG | Arc pib tam sim no (A) | 10-160 Nws | |||

| Arc nres tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5-500 | ||

| Pre-flow lub sij hawm (S) | 0.1-15 | ||||

| Lagging lub sij hawm ntawm roj- - nres (S) | 0.1 ~ 20 | ||||

| TIG pilot arc style | HF arc | ||||

| Tes arc vuam vuam tam sim no (A) | 30-315 : kuv | 40-400 Nws | 50 ~ 500 | ||

| Txias hom | Dej txias / Cua txias | ||||

| Shell tiv thaiv qib | IP21S | ||||

| Rwb thaiv tsev qib | H/B | ||||

WSM -S/YS 400

Inverted DC pulse argon arc vuam tshuab

| Qauv | WSM-400S/YS | ||

| Rated input voltage / zaus | Peb-theem 380V (+/-) 10% 50Hz | ||

| Rated input muaj peev xwm (KVA) | 17.1 | ||

| Rated input tam sim no (A) | 26 | ||

| Rated load sustainability (%) | 60 | ||

| DC qhov tam sim no Vuam tam sim no (A) | 5-400 Nws | ||

| DC mem tes | Peak tam sim no (A) | 5-400 Nws | |

| Base tam sim no (A) | 5-400 Nws | ||

| Pulse lub luag haujlwm (%) | 1 ~ 100 | ||

| Pulse zaus (Hz) | 0.2 ~ 20 | ||

| Pre-flow lub sij hawm (S) | 0.1-15 | ||

| Lagging lub sij hawm ntawm roj- - nres (S) | 0.1 ~ 20 | ||

| Ua hauj lwm style ntawm arc nres tam sim no | Ob-kauj ruam, Plaub-kauj ruam | ||

| TIG pilot arc style | HF arc | ||

| Txias hom | Dej txias / Cua txias | ||

| Shell tiv thaiv qib | IP21S | ||

| Rwb thaiv tsev qib | H/B | ||

Muaj nuj nqi:

DC tas li tam sim no TIG, DC pulse TIG.

Daim ntawv thov kev lag luam:

Petrochemical kev lag luam, siab nkoj, hluav taws xob siv hluav taws xob, nkoj, tsheb kauj vab, nuclear fais fab thiab cov yeeb nkab tso.

Nta:

◆ Lub vaj huam sib luag ua haujlwm nrog cov qauv tsim nyog, kev ua haujlwm nplua nuj thiab kev ua haujlwm yooj yim;

◆ Cov yam ntxwv xws li qhov nce qeeb thiab qhov qis qis ntawm cov hluav taws xob tam sim no, impulse zaus, lub luag hauj lwm piv, lub sij hawm ntawm cov khoom siv roj siab heev thiab cov khoom lag luam roj tuaj yeem raug precisely;

◆ Phau ntawv hlau-arc vuam tuaj yeem kho cov hluav taws xob tam sim no ntawm arc striking thiab thrust, nrog ib qho yooj yim striking ntawm arc thiab tiv thaiv cov adhesion ntawm vuam pas nrig;

◆ Argon arc vuam tuaj yeem tiv thaiv rab phom vuam los ntawm dej depletion;

◆ Nws muaj ob-kauj ruam thiab plaub-kauj ruam vuam tswj hom;Nws yog me dua thiab sib dua thiab yooj yim rau kev txav mus los;

◆ Tam sim no thiab qhov voltage tuaj yeem tshwm sim ib txhij.Lub vuam tam sim no tuaj yeem raug presetly;

◆TIG tuaj yeem xaiv txoj hauv kev ntawm kev nqa lub zog siab ntawm arc tawm tsam;

◆ Lub built-in muaj zog hlau pub system muaj ib tug nplua nuj muaj nuj nqi menus ntawm hlau pub, uas muaj peev xwm ua tau raws li cov txheej txheem sib txawv;

◆ Cov xov hlau pub tus nqi thiab mem tes tam sim no sib tw tau.

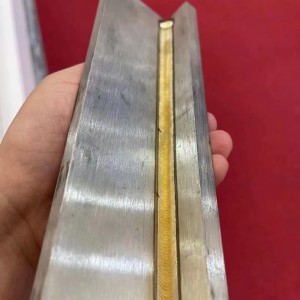

Kev txiav txim siab ntawm Welder

Thaum ob daim hlau nrog cov thickness sib txawv yog butted ua ke, kom tsis txhob muaj kev ntxhov siab loj tshwm sim los ntawm kev hloov pauv sai ntawm ntu ntu, ntug ntawm cov phaj tuab feem ntau maj mam ua kom tiav tib lub thickness ntawm ob npoo.Lub zog zoo li qub thiab qaug zog ntawm pob qij txha yog siab dua lwm cov pob qij txha.Rau kev sib txuas hauv kev sib hloov, kev poob siab lossis kev ua haujlwm hauv qhov kub thiab txias siab, kev sib txuas ntawm pob tw yog feem ntau nyiam.Kev npaj ua ntej vuam ntawm lub puab tsaig yog yooj yim, lub rooj sib txoos yog yooj yim, thiab vuam deformation thiab residual kev nyuaj siab yog me me, yog li nws yog feem ntau siv nyob rau hauv lub installation ntawm cov pob qij txha thiab cov qauv tsis tseem ceeb ntawm qhov chaw.Feem ntau, cov pob qij txha ntawm lub puab tsaig tsis haum rau kev ua haujlwm nyob rau hauv tej yam kev mob xws li alternating loads, corrosive media, siab los yog tsawg kub.Kev siv T-joints thiab kaum pob qij txha feem ntau yog vim kev xav tau ntawm cov qauv.Cov yam ntxwv ua haujlwm ntawm qhov tsis tiav fillet welds ntawm T-joints zoo ib yam li fillet welds ntawm ceg tawv pob qij txha.Thaum lub weld yog perpendicular mus rau cov kev taw qhia ntawm sab nraud quab yuam, nws ua ib tug pem hauv ntej fillet weld.Nyob rau lub sijhawm no, cov duab ntawm qhov chaw weld yuav ua rau cov qib sib txawv ntawm kev ntxhov siab;qhov kev ntxhov siab ntawm kev nkag mus rau fillet weld yog zoo ib yam li ntawm lub pob tw.

Vim li cas thiaj xaiv peb

Peb yog CREATIVE

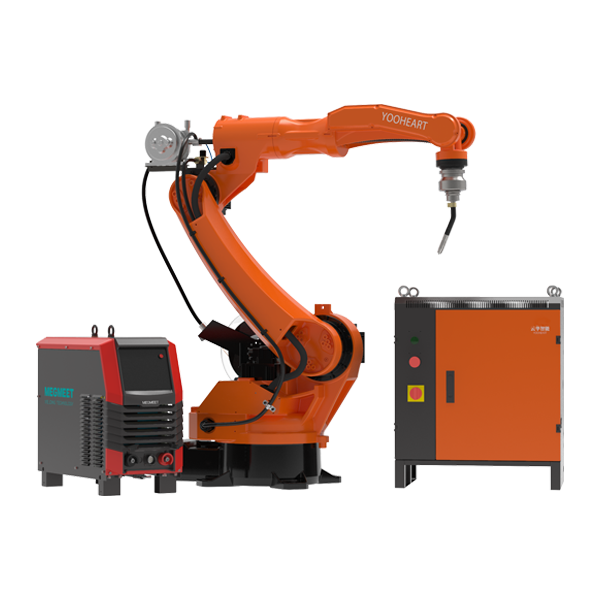

BINGOtsis tu ncua tshawb fawb thiab txhim khontse vuam tshuabcia cov khoom siv vuam ntau duamus thoob ntiaj teb

Peb mob siab rau

Tam sim no nws tau raug cuam tshuam thiab nyiamlos ntawm ntau lub tebchawsyav tom ntej

PEB ZOO SIAB

Peb yuav nqis peev ntau cov peev txheej hauvnruam r & d thiab ntau lawmmus tom ntejyeej tsis nres