TIG welding Robot

Khoom Taw Qhia

GTAW feem ntau yog siv los vuam cov ntu ntawm cov hlau tsis muaj hlau thiab cov hlau tsis muaj hlau xws li txhuas, magnesium, thiab tooj liab alloys. Cov txheej txheem tso cai rau tus neeg teb xov tooj tswj hwm qhov vuam ntau dua li cov txheej txheem sib tw xws li cov hlau thaiv hlau arc vuam thiab roj hlau arc vuam, tso cai rau kom muaj zog dua, zoo dua welds. Txawm li cas los xij, GTAW yog qhov sib piv ntau dua thiab nyuaj rau tus tswv, thiab tsis tas li ntawd, nws qeeb qeeb dua li lwm yam kev siv vuam. Cov txheej txheem muaj feem xyuam, plasma arc vuam, siv lub vuam sib txawv me ntsis los tsim kom pom ntau dua vuam arc thiab vim li ntawd feem ntau automated.

Yunhua siv kev tiv thaiv tshwj xeeb thaum TIG vuam, thiab yuav muaj phau ntawv tshwj xeeb rau tus neeg teb xov tooj, tsuas yog tus neeg teb xov tooj tuaj yeem ua raws li phau ntawv qhia, thiab xyaum ntau zaus, nws tuaj yeem ua tau sai heev.

PRODUCT PARAMETER & DETAILS

| Qauv | WM-315 R | WM-400R | WM-500R | |

| Rated input voltage / zaus | Peb-theem 380V (+/-) 10% 50Hz | |||

| Rated input muaj peev xwm (KVA) | 11.2 | 17.1 | 23.7 ib | |

| Rated input tam sim no (A) | 17 | 26 | 36 | |

| Rated load sustainability (%) | 60 | 60 | 60 | |

| DC thiab tsis tu ncua tam sim no | Vuam curren (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 |

| DC mem tes | Peak tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 |

| Base tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 | |

| Pulse muaj nuj nqi (%) | 1 ~ 100 | 1 ~ 100 | 1 ~ 100 | |

| Pulse zaus (Hz) | 0.2 ~ 20 | |||

| TIG | Arc pib tam sim no (A) | 10-160 Nws | 10-160 Nws | 10-160 Nws |

| Arc nres tam sim no (A) | 5-315 : kuv | 5-400 Nws | 5 ~ 500 | |

| Lub sij hawm ntawm kev nce tam sim no (S) | 0.1 ~ 10 | |||

| Lub sijhawm tam sim no-txo (S) | 0.1 ~ 15 | |||

| Pre-flow lub sij hawm (S) | 0.1 ~ 15 | |||

| Lagging lub sij hawm ntawm gas-stopping (S) | 0.1 ~ 20 | |||

| Ua hauj lwm style ntawm arc nres tam sim no | Ob-kauj ruam, Plaub-kauj ruam | |||

| TIG pilot arc style | HF arc | |||

| Tes arc vuam vuam tam sim no | 30-315 : kuv | 40-400 Nws | 50 ~ 500 | |

| Txias hom | Dej txias | |||

| Shell tiv thaiv qib | 1 P2S | |||

| Rwb thaiv tsev qib | H/B | |||

Daim ntawv thov

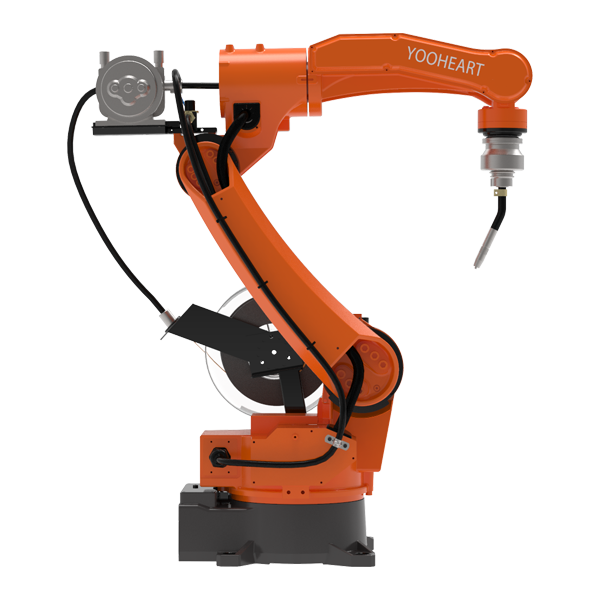

Daim duab 1

Taw qhia

Tig vuam neeg hlau rau Electric Hlau

Pulse Tig vuam txheej txheem rau ntses nplai weld seam.

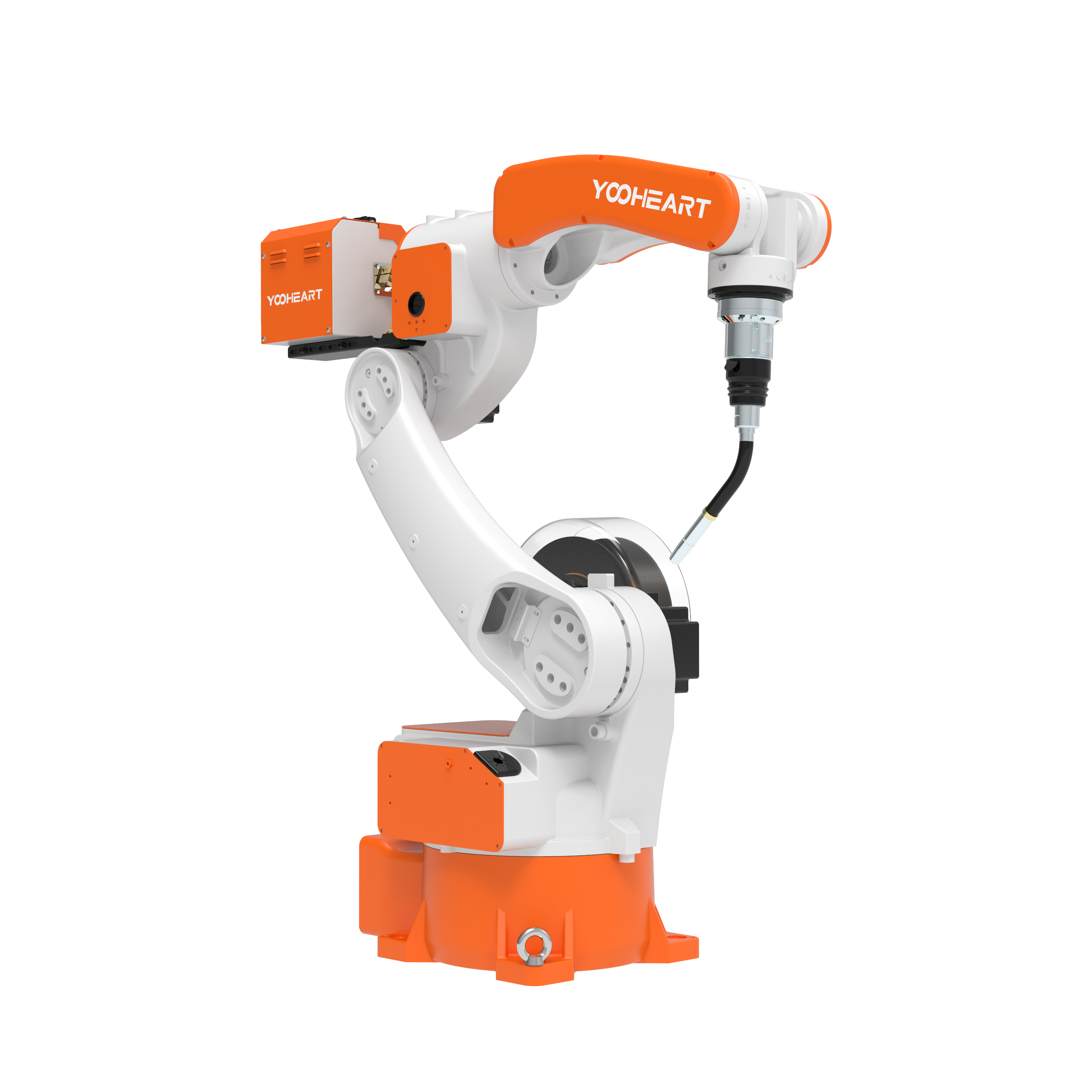

DUA 2

Taw qhia

Tig vuam neeg hlau rau Stainless hlau

Tig arc vuam rau square yeeb nkab vuam.

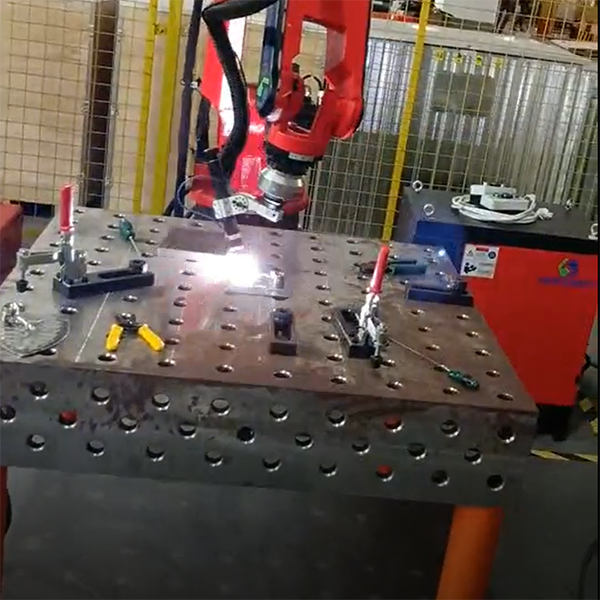

DUA 3

Taw qhia

Parameters ntawm TIG welding welder

Pulse Tig vuam kev ua tau zoo. Thickness: 1.5mm, haum yuam kev: ± 0.2mm.

Kev xa khoom thiab xa khoom

Yunhua tuaj yeem muab cov neeg siv khoom sib txawv ntawm cov khoom xa tuaj. Cov neeg siv khoom tuaj yeem xaiv txoj kev xa khoom los ntawm hiav txwv lossis los ntawm huab cua raws li qhov tseem ceeb tshaj plaws. YOO HEART neeg hlau ntim cov ntaub ntawv tuaj yeem ua tau raws li qhov xav tau ntawm hiav txwv thiab huab cua. Peb yuav npaj tag nrho cov ntaub ntawv xws li PL, daim ntawv pov thawj ntawm keeb kwm, daim ntawv them nqi thiab lwm yam ntaub ntawv. Muaj ib tus neeg ua haujlwm uas nws txoj haujlwm tseem ceeb yog xyuas kom txhua tus neeg hlau tuaj yeem xa mus rau cov neeg siv khoom chaw nres nkoj yam tsis muaj kev cuam tshuam hauv 40 hnub ua haujlwm.

Kev pab cuam tom qab muag

Txhua tus neeg siv khoom yuav tsum paub YOO HEART neeg hlau zoo ua ntej lawv yuav nws. Thaum cov neeg siv khoom muaj ib lub YOO HEART neeg hlau, lawv cov neeg ua haujlwm yuav muaj 3-5 hnub kev cob qhia pub dawb hauv YOO HEART Hoobkas. Yuav muaj pab pawg Wechat lossis WhatsApp pab pawg, peb cov kws tshaj lij uas muaj lub luag haujlwm rau kev pabcuam tomqab muag, hluav taws xob, khoom siv hardware, software, thiab lwm yam, yuav nyob hauv. Yog tias ib qho teeb meem tshwm sim ob zaug, peb cov kws tshaj lij yuav mus rau lub tuam txhab cov neeg siv khoom los daws qhov teeb meem.

FQA

Q1. Dab tsi yog cov ntawv thov zoo tshaj plaws rau cov neeg hlau TIG vuam tshuab?

A.High-ntim, tsawg-ntau daim ntawv thov yog zoo haum rau cov neeg hlau vuam; Txawm li cas los xij, cov ntawv thov qis dua, ntau dua tuaj yeem ua haujlwm yog tias siv nrog cov cuab yeej tsim nyog. Cov tuam txhab yuav tsum xav txog tus nqi ntxiv rau kev siv cuab yeej los txiav txim siab seb lub tshuab vuam tshuab tuaj yeem tseem tuaj yeem muab cov khoom xa rov qab rau thawj zaug peev. Raws li rau TIG vuam, qhov zoo tshaj plaws daim ntawv thov yog nyias nyias thiab hlau.

Q2. Qhov twg siv zoo dua? HF TIG welding lossis Lift TIG vuam?

A. Qhov kev xaiv nrov tshaj plaws thiab zoo tshaj plaws yog kev siv High Frequency pib uas ua rau lub siab zaus arc uas muaj peev xwm ntawm ionizing huab cua thiab bridging qhov sib txawv ntawm tungsten point thiab cov khoom ua haujlwm. Lub High Frequency pib yog ib tug kov-tsawg txoj kev thiab tsim yuav luag cov kab mob tshwj tsis yog tias lub tungsten yog dhau sharpened los yog lub amperage yog tig siab dhau thaum pib. Nws yog ib qho kev xaiv zoo heev rau vuam aluminium, thiab tiag tiag yog qhov kev xaiv nkaus xwb. Tshwj tsis yog tias koj yuav tsum tau vuam Aluminium, koj tsis tas yuav muaj qhov pib siab zaus, tab sis nws yog qhov zoo uas yuav tsum tau vuam AC lossis DC yog tias koj muaj kev xaiv.

Q3. YOO HEART TIG vuam neeg hlau puas siv tau?

A. Yog, peb yog ib qho ntawm ob peb tus neeg tuaj yeem siv lub tshuab nqus tsev thaum TIG vuam. Ntau tus neeg muag khoom hauv khw yuav qhia rau koj tias lawv cov neeg hlau tuaj yeem siv rau TIG vuam, koj tuaj yeem nug nws cov lus nug xws li: yuav ua li cas lim HF?

Q4. Yuav ua li cas teeb tsa lub hwj chim thaum siv TIG vuam?

A.Koj lub tshuab vuam yuav tsum tau teem rau DCEN (Direct tam sim no electrode tsis zoo) tseem hu ua ncaj polarity rau ib qho haujlwm uas yuav tsum tau welded tshwj tsis yog tias lawv cov khoom yog txhuas lossis magnesium. High zaus yog teem rau pib uas yog pom ua nyob rau hauv tam sim no nyob rau hauv inverters. Post ntws yuav tsum tau teem tsawg kawg yog 10 vib nas this yam tsawg kawg nkaus. Yog tias A/C nyob tam sim no nws tau teem rau qhov chaw pib uas coincides nrog DCEN. Teem lub contactor thiab amperage hloov mus rau tej thaj chaw deb chaw. Yog hais tias cov khoom uas yuav tsum tau welded yog txhuas polarity yuav tsum tau teem rau A / C, A / C tshuav nyiaj li cas yuav tsum tau teem rau li 7 thiab siab zaus mov yuav tsum tas mus li.

Q5. Yuav ua li cas teeb tsa Gas thaum lub sij hawm TIG vuam?

A. TIG vuam siv cov roj inert los tiv thaiv qhov chaw vuam los ntawm kev sib kis. Yog li no cov roj inert kuj tau teev tias yog cov roj tiv thaiv. Nyob rau hauv txhua rooj plaub nws yuav tsum yog argon thiab tsis muaj lwm yam inert gas xws li neon los yog xenon thiab lwm yam tshwj xeeb tshaj yog yog hais tias TIG vuam yuav tsum tau ua. Nws yuav tsum tau teem ib ncig ntawm 15 cfh. Rau vuam aluminium ib leeg koj tuaj yeem siv 50/50 ua ke ntawm argon thiab helium.