Daim ntawv thov ntawm vuam robots yuav tsum nruj me ntsis tswj qhov kev npaj zoo ntawm qhov chaw thiab txhim kho lub sib dhos raug ntawm weldments.Qhov zoo ntawm qhov chaw, qhov luaj li cas thiab kev sib dhos qhov tseeb ntawm cov khoom yuav cuam tshuam rau cov vuam seam taug qab cov nyhuv.Qhov zoo ntawm qhov kev npaj thiab qhov tseeb ntawm kev sib dhos weldment tuaj yeem txhim kho los ntawm cov hauv qab no.

(1) Muab cov txheej txheem vuam tshwj xeeb rau vuam neeg hlau, thiab ua cov txheej txheem nruj ntawm qhov loj ntawm qhov chaw, vuam grooves, thiab sib dhos qhov ntev.Feem ntau, qhov kam rau ntawm qhov chaw thiab qhov zawj qhov ntev yog tswj tsis pub dhau ± 0.8 hli, thiab qhov sib dhos qhov yuam kev yog tswj tsis pub dhau ± 1.5 hli.Qhov tshwm sim ntawm vuam qhov tsis xws li qhov pores thiab undercuts hauv vuam tuaj yeem txo qis heev.

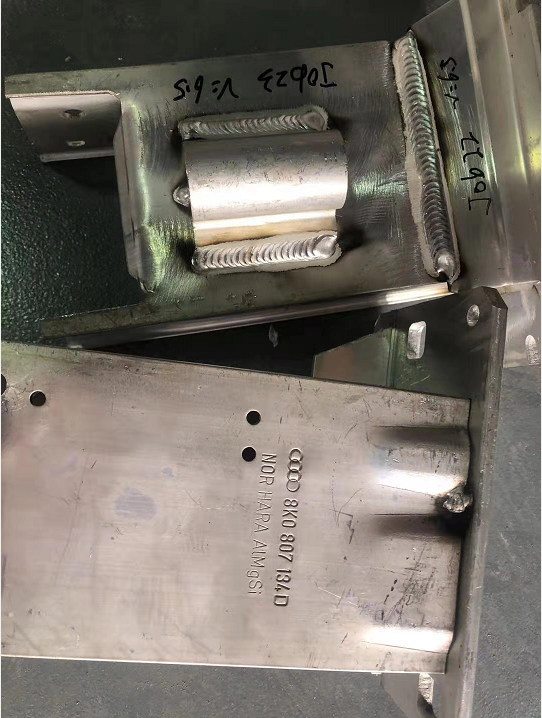

(2) Siv cov cuab yeej sib dhos ua haujlwm siab los txhim kho qhov tseeb ntawm kev sib dhos.

(3) Vuam seams yuav tsum tau ntxuav, tsis muaj roj, xeb, vuam slag, txiav slag, thiab lwm yam., thiab solderable primers raug tso cai.Txwv tsis pub, nws yuav cuam tshuam qhov kev vam meej ntawm arc ignition.Tack welding yog hloov los ntawm electrode welding mus rau gas shielded vuam.Nyob rau tib lub sij hawm, qhov chaw vuam qhov chaw yog polished kom tsis txhob seem slag crusts los yog pores vim tack welding, thiaj li tsis txhob arc instability thiab txawm spatter.

Post lub sij hawm: Sep-11-2021